Fixed Stationary Platen and Movable Platen introduction in Injection Molding Machine

– By Zafar Kamal

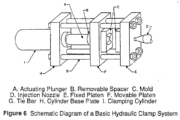

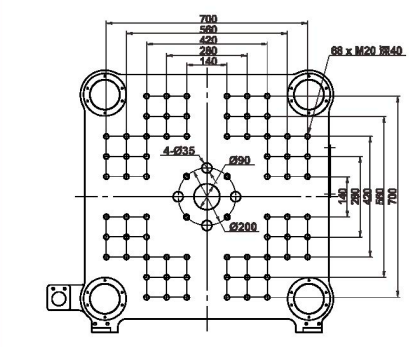

The platens of a molding press are heavy steel plates to which the halves of the mold are attached. In most machine operations, one platen is rigidly mounted and is correspondingly called the stationary platen(fixed platen/first platen). The other (movable platen/second platen) is mounted so that it can be moved as the clamp mechanism is opened and closed. The molds are attached to these plates either by direct bolting or through the use of clamps which are attached to the plates in a series of carefully spaced, drilled and tapped holes. This method provides a great degree of versatility to any given size machine. The stationary platen(fixed platen/first platen) must provide an entry for the nozzle of the plasticizing chamber. A register ring or location device is provided in this plate to properly align the mold with the nozzle.

The movable platen must incorporate a device for actuating the part ejection system, most commonly by means of some mechanical knockout bar extensions which pass through the platen and contact the knockout plate built into the mold base. Some machines are equipped with hydraulic knockout arrangements whose actuating cylinders are mounted within the confines of the stationary platen.

Because of the tremendous forces that may be applied during the clamping and injection portion of the cycle, the mold platens are ruggedly build. As the physical size of the press is increased, larger molds may be accommodated, and consequently the weight that may be suspended from the platen becomes greater. It should also be recognized that as the press size increases there is usually a significant increase in the clamp force that is available. The platen then, must not only be strong enough to support the tooling but also be capable of withstanding the bending or deflection action caused by the clamping force. Any serious distortion of the platen can cause the mold to flash and can lead to severe wear and damage to the press itself.