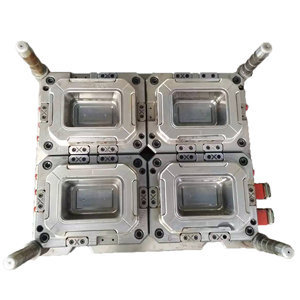

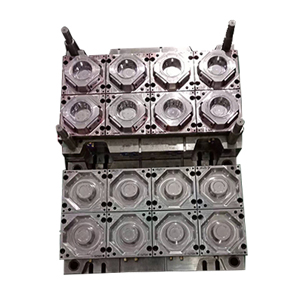

What is “Thin Wall Injection Molding”?

Thin wall parts are classed as such based on their flow length to wall thickness (or L/t) ratio. Each plastic material has different flow properties so each family of resins has different maximum L/t ratios. The table below shows maximum L/t ratios for some common materials – figures that approach these high values would be considered thin walled. These values are based on a 2.0mm wall section,maximum L/t ratios reduce as the wall thickness gets thinner.

- Wall thickness often <0.6 mm.

- Parts with flow ratio > 150.

- High Injection pressure.

- High Injection speed.

- Applications for containers in packaging and storage as well as disposable use.

| Material |

ABS |

PA |

HDPE |

LDPE |

PP |

POM |

PS |

| Maximum L/t Ratio |

170/1 |

150/1 |

225/1 |

275/1 |

250/1 |

150/1 |

200/1 |

|

*Flow length & thinness ratio of normal injection materials…

|