Clamping System Rating of Injection Molding Machine

– By Zafar Kamal

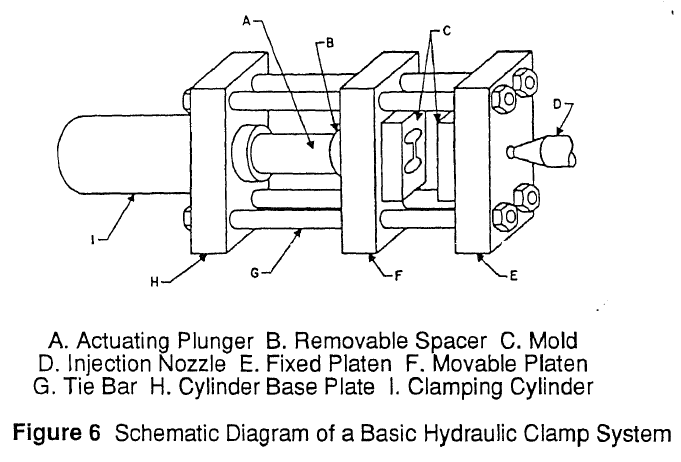

The clamping system for the injection-molding machines have nominal ratings in tons of clamp force that can be exerted. Although machines are built to certain standards to provide a given force, individual units can vary somewhat from their design ratings. A large opposing force will be required to keep the mold closed and thus produce acceptable molded parts. As the part depth becomes greater and as the wall thickness becomes less, the opposing clamp force will become greater. Although the injection pressure in a given system may be in the range of 15000 to 20000 psi.

| Clamp force (tons) | Shot size (ounces) |

|---|---|

| 10 – 25 | upto 2 |

| 25 – 50 | 1 – 4 |

| 50 – 100 | 2-10 |

| 100 – 150 | 3 -15 |

| 150 – 200 | 4 – 25 |

| 200 – 250 | 6 – 30 |

| 250 – 300 | 8 – 40 |

| 300 – 350 | 10 -50 |

| 350 – 400 | 20 – 60 |

| 400 – 450 | 25 – 70 |

| 450 500 | 30 – 80 |

| 500 – 600 | 40 – 100 |

| 600 – 700 | 50 -120 |

| 700 – 800 | 60 – 140 |

| 800 – 900 | 70 – 180 |

| 900 – 1000 | 80 – 200 |

| 1000 – 1200 | 100 – 300 |

| 1200 – 1500 | 120 – 400 |

| 1500 – 2000 | 150 – 600 |

| 2000 – 4000 | 200 – 900 |

Pressure drops in the cylinder, through the nozzle, and into the mold cause a loss in the total available pressure and consequently, the effective pressure within the cavity on the material may be only 25 to 50 percent of the original starting pressure. With screw-type plasticators injection pressures are reduced primarily because of the greater degree of homogenization of the melt.