Venting of Plastic Injection Molds

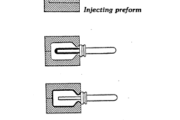

Before the plastic melt is injected, the cavity in the closed mould contains air. When the melt enters the injection mould, if the air cannot escape it become compressed.

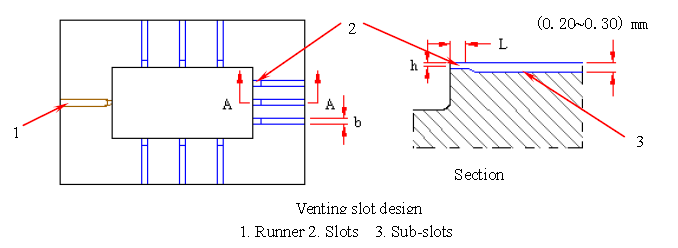

At worst this may effect the filling, but in any case the sudden compression of the air causes heating. This may be sufficient to burn the plastic and the mould surface at the local hot spots. To alleviate this problem, vents are machined into the mating surfaces of the plastic injection mould to allow the air to escape.