Stretch Blow Molding Technique Introduction

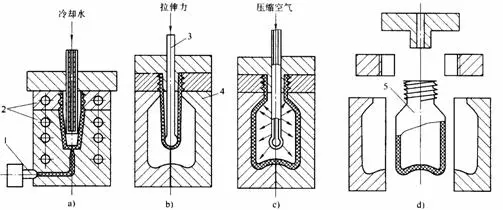

The stretch-blow process can give many resins improved physical and barrier properties. In biaxial orientation, bottles are stretched lengthwise by an external gripper, or by internal stretch rod, and then stretch radially by blow air to form the finished container against the mold walls.

This process aligns the molecules along two planes, providing additional strength and even more important, better barrier properties then are possible without biaxial orientation. Other advantages include better clarity, increase impact strength, or toughness, and reduce creep. The actual increase is dependent on the ratio of blow-up in each direction.

Stretch blow molding is possible for thermoplastic materials such as PET, PVC, polystyrene, acrylonitrile, polypropylene, and acetals. The amorphorous material with the wide range of thermoplasticity are easier to Stretch blow than the partially crystalline types. With the partially crystalline type, if the crystallizing is too rapid, the bottle is virtually destroyed.

Stretch-blow processing can be separated into two categories: in-line and two-stage. In-line processing is done on a single machine, while two stage processing requires an injection line to produce preforms, and a reheat blow machine to make the finished bottles. In the in-line, an injection molded parison passes through the conditioning stations that bring it to the proper orientation temperature. A rather tight temperature profile is held in the axial direction of the preform. Advantages of the in-line systems are that heat history is minimized, and the preform can be programmed for optimal material distribution if it is maintained under continuous control.

With the two-stage, the process uses extruded or injection molded preforms that have been cooled, and indexes them through an oven that reheats them to the proper orientation-blow temperature. Advantages of these processes can be the fact that scrap production is minimized, improved thread finis, higher output rates, and the capability to stockpile preforms.

– By Zafar Kamal