Opening and Closing System for Mold in Injection Molding Machines

– By Zafar Kamal

Opening and Closing System for Mold

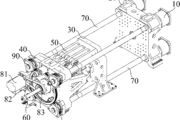

The function of the clamp end of an injection molding machine is opening and closing of the mold. At the same time it must have a means of keeping the mold tightly closed during the injection cycle. This function is performed by a mechanical or hydraulic device for traversing the movable platen of the machine.

Mechanical devices for moving and locking the movable platen consist of toggle systems which can be single or multiple, mounted between the movable platen and the fixed tailstock of the clamp unit. With the toggle in the open or folded position the movable and stationary platens are separated and the mold is open. When the mold is closed the toggle arm form a continuous beam structure that can support the full clamp force of the machine.

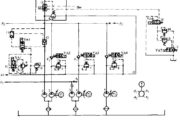

Clamp systems can be also be direct hydraulically operated. Hydraulic clamp cylinders can develop large clamp forces but they are slow acting as compared with toggle mechanisms. Hydraulic clamp systems are usually found on the larger capacity machines where toggle linkages that can support comparable clamping pressure may become too large and cumbersome for practical purposes in addition to the simple mechanical-toggle and hydraulic systems many of the newest machines offer combinations. Small, fast-acting toggles are used to actuate the platen-moving mechanism, coupled with the hydraulic cylinders which into play during the final clamping and the actual injection cycle to apply the full clamp pressure of the machine.