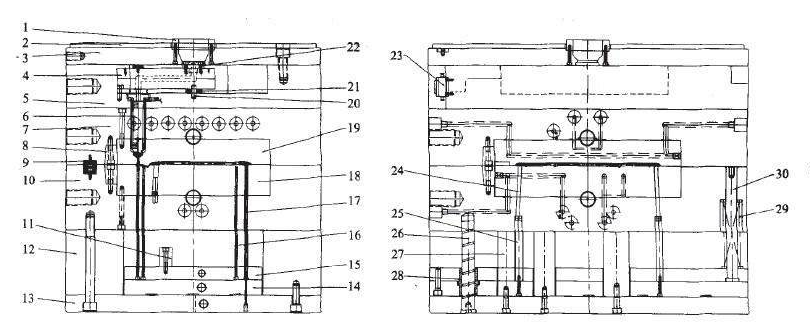

Mold Temperature Control in Plastic Injection Molds

If we want to get efficient moulding, we should control the mould temperature and this is done by means of passing fluid through a suitable arrangement of channel in the mould. The rate at which the moulding cools affect the total cycle time as well as the surface finish, tolerances, distortion and internal stresses of the moulded article. High mould temperature improves the surface gloss and tend to eliminate voids. If the mould temperature is too low then the material may freeze in the cavity before it is filled.