Mold Set-up Guides on Toshiba Injection Molding Machines

Mold Set-up Preparation

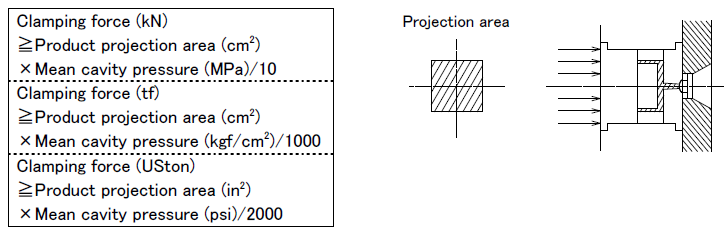

Check if the mold matches the injection molding machine.

[1] Check if mold sizes matches the injection molding machine.

Mold width

H < Distance between tie rods, or Mold height,

V < Distance between tie rods

* Refer to the specifications for the Distance between tie rods H / Max. mold height / Min. mold height.

[2] Injection volume check

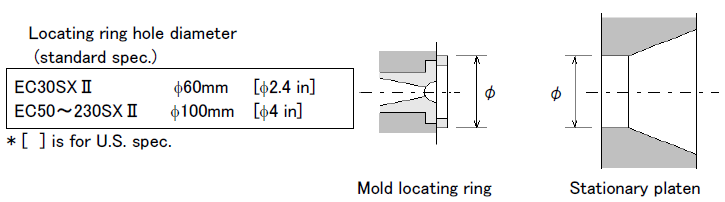

* The locating ring hole diameter may be changed according to the machine specification. Refer to the attached drawing, MOLD MOUNTING SPACE for checking.

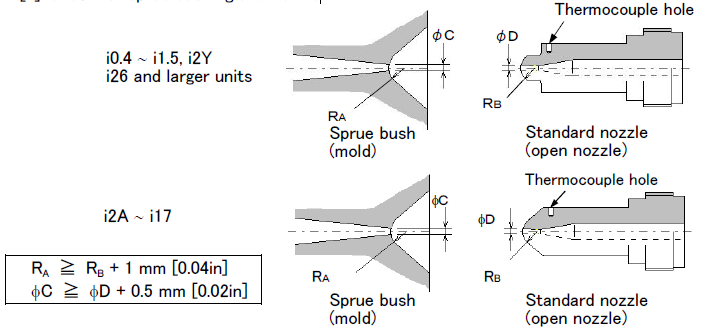

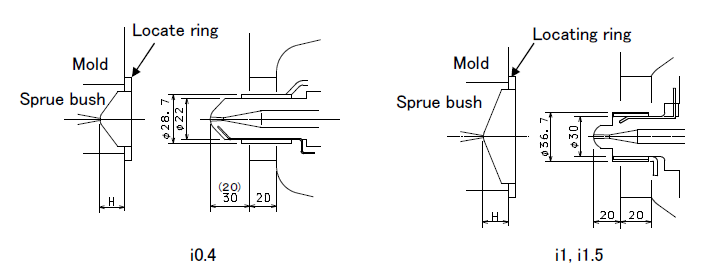

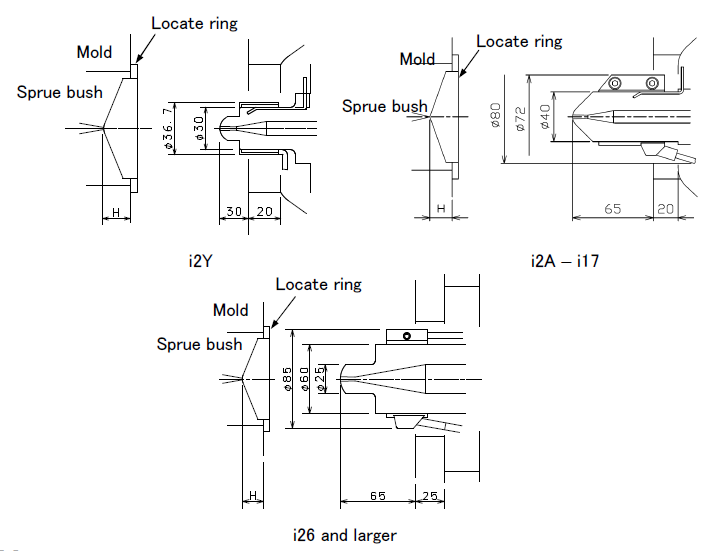

[5] Nozzle touch check

[5] Nozzle touch check

H < Nozzle projection amount

[message type="custom"]

[one_half]

* Projection amount of the standard nozzle

i0.4 unit: 30 mm [1.18in]

i1 and i1.5 units: 20 mm [0.79in]

i2Y unit: 30 mm [1.18in]

i2A and larger units: 65 mm [2.56in]

[/one_half]

[one_half_last]

* Check if the clearances of nozzle heater and thermocouple to sprue bushing hole are secured.

[/one_half_last]

[/message]

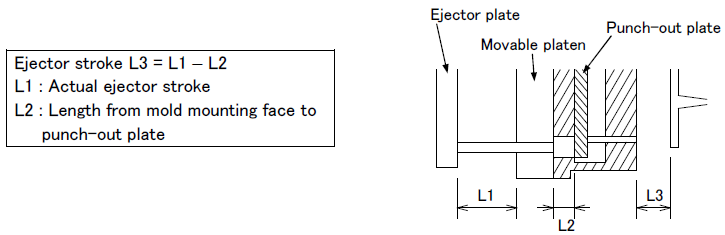

[7] Checking for ejecting rod position, diameter, and length

[7] Checking for ejecting rod position, diameter, and length