Clamp Unit`s Mechanical Configuration and Movement on Toshiba All-electric Injection Molding Makers

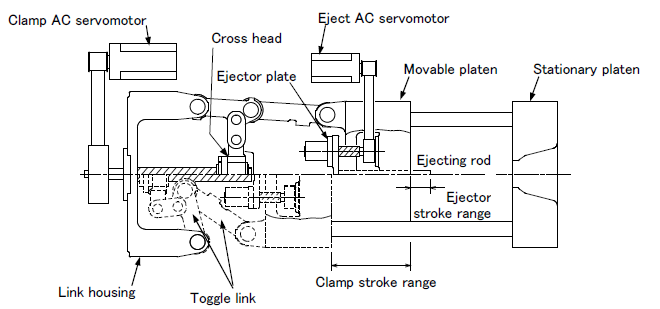

[1] Mold open / closeAC servomotor and toggle link mechanisms are installed to open and close the mold.

・ Operation principle

The ball screw fixed to the movable platen is driven by the servo motor to open and close the movable platen.

・ Stroke range

The stroke range of the movable platen is fixed by the controller setting.

・ Operation principle

The ball screw fixed to the ejector plate is driven by the servomotor to advance or retract the ejecting rods.

・ Stroke range

The stroke range of the ejecting rod advance/retract is fixed by the controller setting.

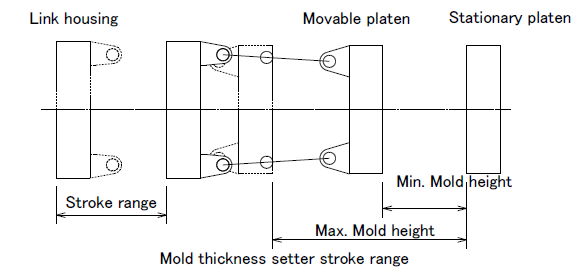

・ Operation principle

The toggle type mold clamp unit requires adjusting the link mechanism position according to the mold thickness to be used. Four pieces of tie rod nuts fixed to the link housing are driven by the geared motor by way of gears to adjust the mold thickness.

・ Stroke range

Proximity switches are installed on both the advance and retract limits of the mold thickness setter to determine stroke range. On reaching the limit, the mold thickness setter stops adjusting operation.