Mold Cooling on Injection Moulding

– By Zafar Kamal

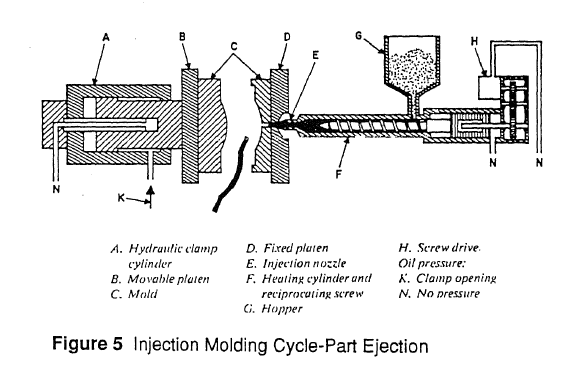

In any consideration of the injection molding process the subject of the mold cooling must not be overlooked. Obviously, if hot polymer is to set up within the mold cavity, the material must be cooled sufficiently to solidify it and allow the molded part to be removed from the mold.

This, in essence, is the mold-cooling portion of any cycle, and will vary in time and temperature depending upon the geometry of the part and the choice of thermoplastic material.

Mold cooling can be considered as taking place with the mold at any temperature below the inlet temperature of the plastic melt. Most commonly, the mold surface will be maintained at a temperature ranging from 30 to 40 degree F upto 120 to 150 degree F. The successful molder will strive to achieve as uniform temperature across the face of the mold as possible ‘to develop within the mold a uniform shrinkage and thereby reduce the tendency to part warpage. When the injection mold is being designed and constructed, definite consideration must be given to the proper layout of the necessary cooling channels in both halves of the tool.

Remember that tool performance and the quality of the molded part depend largely on the ability to transfer heat rapidly and uniformly. In order to control shrinkage and warpage, it may be necessary to operate the mold at an elevated temperature level, with a somewhat longer cycle. When the molded part has a relatively thin wall section, and high speed production is a must, the mold may be operated using refrigerated cooling water. These are the extremes; normal molding operations will fall between these limits.

Obviously the heat necessary to effectively melt the plastic is the same quantity of heat that must be removed before the part can be ejected from the mold. As the heat content of the plastic increases and as the melt temperature goes up, it becomes even more important that the cooling system be capable of removing this greater amount of heat rapidly and efficiently. The way a mold is

cooled is of great importance to the injection molder. Because lower ‘ mold temperatures make for increased part stiffness and strength, improved clarity, minimum shrinkage, and substantially reduce cycle times.

Molds are usually water cooled. But there is a imit to the number of cooling channels that can be incorporated into a mold base. These channels should be positioned so that the heat transfer from the melt is as uniform as possible. To obtain balanced heat transfer, greater cooling must often be provided around the thicker parts of the molded item.

Minimum warpage calls for high mold temperature; it also requires that the entire piece be cooled at nearly the same rate. This, in turn, calls for low temperature around the cavity gates and less cooling at the mold sections farthest from the gate area. To obtain fast cycle, it is important that the hottest portion of the mold, adjacent to the gating or sprue, receive the most concentrated cooling to minimize the total time required for the part to cool in the mold.

Having the mold too cold is risky for two reasons: It may result in short shots, and may yield molded parts with built -in stresses which can result in later stress cracking of parts.