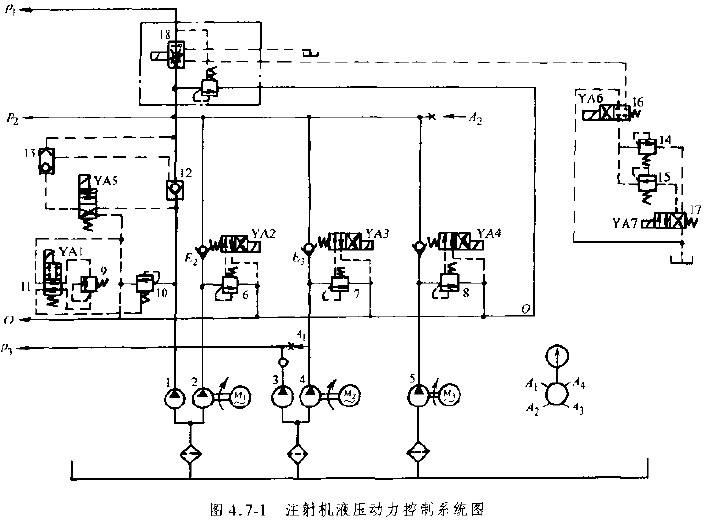

Hydraulic System for Injection Molding Machines

– By Zafar Kamal

The function of the hydraulic system in injection molding machine is to transmit the power from electric motor to the various moving parts of the machine, and to control the power. An electrical control system regulates the hydraulic system to control the direction, force, speed, and sequence of the machine cycle.

The basic components of the hydraulic system are:

1-fluid reservoir

2-pumps

3-valves

4-cylinders

5-hydraulic motors

The hydraulic fluids transmits the power throughout the hydraulic system, and lubricates the pumps and valves. It is important to follow the recommendations of the machine manufacturer or the hydraulic-equipment supplier in selecting the fluid to be used.

The hydraulic lines form passageways in which the fluid from one component to the other in the circuit. The lines may be seamless steel tubes, hoses, or the hydraulic oil may flow through drilled manifolds. The reservoir is simply a storage tank for the hydraulic fluid. In addition, it helps to keep the fluid clean by allowing contaminants to settle out, and it also minimizes turbulence, and dissipates heat.