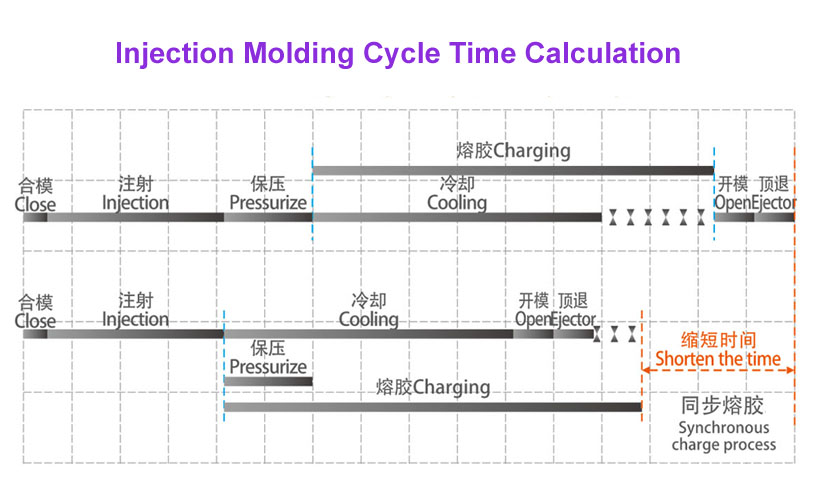

Injection molding cycle time calculation is one of the most important works for an injection molding engineer. Injection molding is a cyclic process. In order to calculate the cycle time, you should calculate operating cycle time for all the molding machine`s movement. The whole operating cycle time includes injection time/filling time, Pressurized Holding Time, Polymer Melting/Charging Time, Cooling Tim, Machines basic movement(Mold open & close) operating Time, Ejection, Drop, Robot Time, etc.

Total injection molding production cycle time calculation formula:

T=Ti + Tp + +Ts + Tm + Tc + To +Te

Ti: Total Injection Time/Filling Time

Tp: Total Pressurized Holding Time

Ts: Total Screw Driving Time

Tm: Total Melting/Charging Time

Tc: Total Cooling Time

To: Total Operating Time

Te: Total Ejection, Drop, Robot Time

Total Injection Holding Time in Injection Molding Cycle Time Calculation

The storage and injection holding time should be determined according to the polymer properties, product shape and quality requirements (appearance, size, etc.). It is related to many factors such as injection pressure, injection rate, screw rotation, back pressure and temperature, and should be guaranteed Seek the shortest time under the premise of quality. When estimating the storage time of injection molded parts, it is generally calculated between 65% and 85% of the maximum plasticizing capacity (g/s) of the injection molding machine. The injection process is usually divided into 3 stages (slow-fast-slow). Below is the estimated cycle time calculation formula:

Ti=W/20~50%V + t

Ti: total injection molding cycle time

W: The total amount of shot weight (the weight of a single product x the number of points + the weight of the nozzle)

V: Maximum injection speed of injection molding machine (grams/second)

t: a driven time for the screw to start and stop

Pressurized Holding Time

The Injection pressurized holding time is before the cooling time. Mostly we can treat it as the cooling time. As the plastic is cooling fast so the pressurized holding time is short. We assume it from 1 to 3 seconds depends on the thickness of the products.

Screw Driving Time in Injection Molding Cycle Time Calculating

80T~200T: Normally takes 1~2S

200T~500T: Normally takes 2~3S

500T~1000T: Normally takes 3~4S

Plastic Cooling Time in Injection Molding Cycle Time Calculation

The dwell time is the time elapsed from the time the cavity is filled to the end of the dwell.

The choice of holding time generally depends on the product’s requirements for appearance shrinkage, size, and deformation:

Cooling time refers to the time elapsed from the end of holding pressure to the opening of the mold. The length of the cooling time is affected by the product shape, wall thickness, mold cooling water design, mold temperature, melt properties and other factors. On the premise of ensuring a better quality of parts, the cooling time should be shortened as much as possible. When the product is fixed, the design of the mold cooling water is a key factor affecting the length of the cooling time.

The attached table assumes that the mold temperature is uniform at 25 degrees, and the product is a flat plate shape and the required cooling time under different wall thickness conditions.

| Material | Cooling Time ( Seconds ) | |||||

|---|---|---|---|---|---|---|

| Material | Thickness 1mm | Thickness 2mm | Thickness 3mm | Thickness 4mm | Thickness 5mm | Thickness 6mm |

| ABS | 1.8 | 7 | 15.8 | 28.4 | 44.4 | 63.4 |

| PS | 1.3 | 5.4 | 12.1 | 21.4 | 33.5 | 48.4 |

| HDPE | 2.9 | 11.6 | 26.1 | 46.4 | 72.5 | 104 |

| LDPE | 3.2 | 12.6 | 28.4 | 50.1 | 79 | 114 |

| PA66 | 1.6 | 6.4 | 14.4 | 25.6 | 40 | 57.6 |

| PC | 2.1 | 8.2 | 18.5 | 32.8 | 51.5 | 74.2 |

| PMMA | 2.3 | 9 | 20.3 | 36.2 | 56.5 | 81.4 |

| POM | 1.9 | 7.7 | 17.3 | 30.7 | 48 | 69.2 |

| PP | 2.5 | 9.9 | 22.3 | 39.5 | 61.8 | 88.9 |

| PVC (soft) | 2.2 | 8.9 | 20.1 | 35.7 | 55.8 | 80.3 |

| PVC(hard) | 2.7 | 10.7 | 24.3 | 43 | 67.3 | 96.8 |

Plastic Melting/Charging Time in Injection Molding Cycle Time Calculation

The plastic melting time mostly depends on the injection molding machine`s plasticizing capacity. You can get the molding machine plasticizing capacity number on their specification sheet. Then you will need to assume the plastic part`s injection weight including the runners. And don`t forget to plus the mold cavities to have the total shot weight number. So you can use the shot weight divide the plasticizing capacity to have the plastic charging time.

The plastic charging time`s formula as below:

plastic charging time = Plastic shot weight / plasticizing capacity

Injection Molding Machine`s operating cycle time

The mold opening and closing time is affected by the size of the machine, the mold structure, and other factors. The core pulling structure (row position) on the mold, the mold opening, and closing rack drive mechanism, the three-plate mold (fine nozzle) mechanism, etc. All of them will affect the opening and closing time. Generally, we take below time as the machine`s operating cycle time with experience:

80T~200T: 4~8S

200T~500T: 6~10S

500T~1000T: 8~15S.

Product Ejection Time in Injection Molding Cycle Time Calculation

The ejection time is affected by ejection speed, ejection stroke, pickup method (automatic, manual, manipulator), automatic drop is generally only used for products with low appearance requirements (internal parts), ejection time Generally take 0.5~2S. When the robot takes the product, after the product leaves the range of the mold, the mold can start to close the mold and move the part. The item picking time is generally 1~3S for light products, It may be longer like 3~8s for heavy products like pallets, fruit buckets, 90L packing containers, etc.

The injection molding operating cycle formula is to add all the operating cycle time mentioned above. This injection molding cycle time formula is very simple but you need some time to collect all the data. I had organized the injection mold cycle time calculation formula in excel. Please fill the contact form below and we will send it to you by email.