The clamping force calculation of the injection molding machine is a compulsory course for all the injection molding engineers. Let’s talk about the calculation method of the clamping force in injection molding.

The clamping force of the injection molding machine, also known as the clamping force, is the key to the molding of injection products. If the clamping force is too small, it will cause the product to have flash or lack of material.

Too big clamping force will result in a waste resource and will cause premature aging of hydraulic components and mechanical structure wear.

There and many injection molding machine tonnage calculation formulae. Below we will explain how to calculate clamping force with 4 clamping force formula one by one.

Empirical formula: the core idea-to calculate the clamping force through the clamping force constant

Calculation formula:

clamping force = clamping force constant x projected area of the product

p=kps

Remarks:

p=clamping force (t);

kp=clamping force constant (t/cm2),

s=projected area of the product on the template (cm2).

There are 4 clamping force calculation formulae to calculate the clamping force of an injection molding machine:

Clamping Force Calculation Formula 1: Empirical formula 1

Clamping force (T) = Clamping force constant Kp*product projected area S (CM*CM)

| Material | Kp experience value | Material | Kp experience value |

|---|---|---|---|

| PS | 0.32 | PE | 0.32 |

| PP | 0.32 | ABS | 0.30~0.48 |

| PA | 0.64~0.72 | POM | 0.64~0.72 |

| Add glass fiber | 0.64~0.72 | Other engineering plastics | 0.64~0.8 |

| * The data above is according to the experience. It`s not for precise calculation. | |||

Calculated from the above formula:

P=Kp*S=0.32*410=131.2(T),

So a 150T injection molding machine should be okay for this application.

Clamping Force Calculation Formula 2: Empirical formula 2

P=350bar*S(cm^2)/1000.

As in the above application, The injection molder clamping force should be 350*410/1000=143.5T. So choose a 150T injection molding machine will be okay.

The above two clamping force calculation formula are rough calculation methods, the following is a more accurate calculation method:

Clamping Force Calculation Formula 3:

There are two important factors to calculate the clamping force: 1. Projection area 2. Cavity pressure

1. The projected area (S) is the largest area viewed along the opening and closing of the mold.

2. Determination of cavity pressure (P)

The cavity pressure is affected by the following factors

(1) Number and location of gates

(2) Gate size

(3) The wall thickness of the product

(4) The viscosity characteristics of the plastic used

(5) Injection speed

3.1 Grouping of flow characteristics of thermoplastics

| Material | Viscosity (Flowability) Grade K。 | Material | Viscosity (Flowability) Grade K。 |

|---|---|---|---|

| GPPS | 1.0 | HIPS | 1.0 |

| TPS | 1.0 | PS | 1.0 |

| PE | 1.0 | PP | 1.0 |

| PA | 1.33 | PBT | 1.33 |

| PETP | 1.33 | CA | 1.4 |

| CAB | 1.4 | CAP | 1.4 |

| CP | 1.4 | EVA | 1.4 |

| PEEL | 1.4 | PUR | 1.4 |

| TPU | 1.4 | PPVC | 1.4 |

| ABS | 1.5 | ASA | 1.5 |

| ASA | 1.5 | SAN | 1.5 |

| MBS | 1.5 | PPS | 1.5 |

| PPOM | 1.5 | BDS | 1.5 |

| POM | 1.5 | PMMA | 1.61 |

| PC | 1.61 | PC/ABS | 1.61 |

| PC/PBT | 1.61 | PC | 1.8 |

| PES | 1.8 | PSU | 1.8 |

| PEI | 1.8 | PEEK | 1.8 |

| UPVC | 1.8 | Add Fiber Glass | 1.8 |

| Other Engineering Plastic | 1.8 | ||

| * Above plastic viscosity the most pick up value for experience injection machine`s tonage calculation. | |||

Each of the above groups of plastics has a viscosity (flowability) grade. The relative viscosity grades of each group of plastics are as follows:

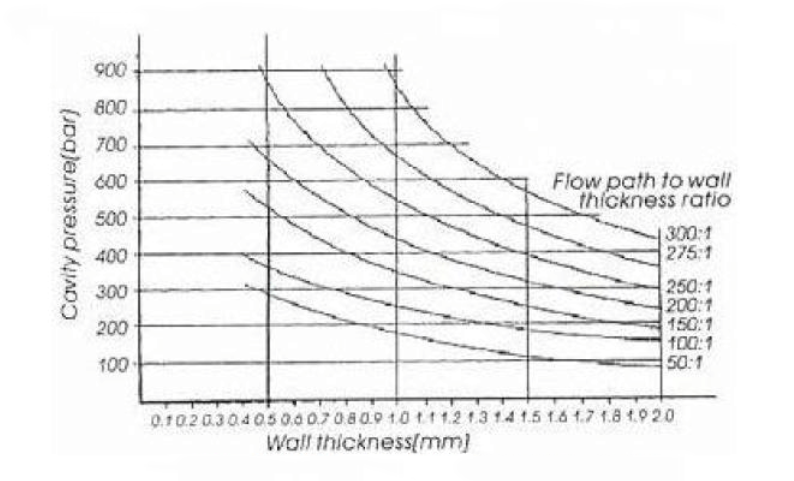

3.3 The cavity pressure is determined by the ratio of wall thickness, process and wall thickness

Look up the table and get P0•P=P0•K (multiplication constant)

3.4 Determination of clamping force (F)

F=P•S= P0•K•S

For example injection application: clamping force calculation of how big machine it will need for polycarbonate (PC) lamp holder

As shown in the picture is a round PC plastic lamp holder, its outer diameter is 220mm, the wall thickness range is 1.9-2.1mm, and it has a pin-shaped center gate designed. The longest flow of parts is 200mm.

The largest melt flow resistance occurs at the thinnest wall thickness (ie 1.9mm), so the value of 1.9mm should be used when calculating the required injection pressure.

(1) Calculation of process/wall thickness ratio

Process / wall thickness = the longest process of molten material / the thinnest part wall thickness = 200mm/1.9mm=105:1

(2) Application of cavity pressure/wall thickness graph

The figure provides the relationship between cavity pressure and wall thickness and process/wall thickness ratio. From the figure, it can be seen that the wall thickness of 1.9mm, and the cavity pressure of the injection piece with the process/wall thickness ratio of 105:1 is 160 Bar. It should be noted here that all The data are all using the first group of plastics. For other groups of plastics, we should multiply the corresponding multiplication constant K.

(3) Determine the numerical value of PC cavity pressure

The flow properties of PC plastic belong to the sixth group of viscosity grades. Compared with the first group, the viscosity of PC is 1.7-1.9 times of theirs, and the different viscosity is reflected in the cavity pressure, so the cavity pressure for the production of PC lamp holders should be 160bar×K (PC viscosity grade), P=160×1.9bar=304bar For safety reasons, we take 1.9 times.

(4) Projected area value of PC lamp holder

S=π×Lamp holder outer diameter 2/4=3.14×22×22/4 (cm2)=380cm2

(5) Clamping force of PC lamp holder

F=P•S=304bar•380cm2=304kg/cm2•380 cm2=115520Kg or 115.5Ton, so 120T can be used.

This calculation formula is the most precise clamping force calculation for injection moulding without professional software that works on the computer.

Clamping Force Calculation method 4:

Use CAE software to calculate the clamping force (MOLDFLOW, etc.).

The main basis for the classification of injection molding machines is the clamping force. In the past, the clamping force of large machines was large, and that of small machines was small. This is the traditional way of thinking. It seems that clamping force is the main indicator to measure the size of the machine. However, as the market becomes more and more subdivided, the clamping force of the machine can no longer fully evaluate the size of the machine, and more and more special machines have begun to appear.

For example, when I produce thick-walled products, I need a large amount of glue and a small clamping force. This is different from the design idea of a traditional machine. The mold plate of the injection molding machine can be slightly rigid and the clamping force can be small. The screw can be thicker, the thread can be deeper, the mold opening distance is larger, and the mold opening and closing speed is slower.

But when I make thin-walled products, I need high clamping force, small melt volume, small mold opening distance, and short cycle time. At this time, the design is different. The rigidity of the injection molding machine template is higher. , The clamping force should be high, the screw should be small, the opening distance should be small, and the opening and closing distance should be fast.

For example, when we make PVC, PA, PS products, the screw design has its own characteristics. The production of precision products requires very high equipment repeatability.

Therefore, the clamping force is the main parameter to measure the machine, but when judging a machine, it depends on the comprehensive evaluation of other parameters.

Above are 4 methods to calculate the clamping force for an injection molding machine. There are 2 simple clamping force formula and 1 precise clamping force formula we mostly used in daily working.

We had prepared an excel format clamp tonnage calculator for the injection moulding machine tonnage calculation. You can fill below contact form and get it free.