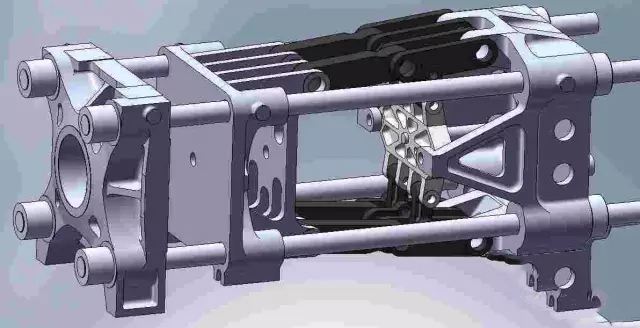

Clamping System Introduction in Injection Molding Machine

– By Zafar Kamal

The function of the clamp of the injection molding machine is twofold. The fixed one is called platen and the other one is movable support the two halves of the injection mold and open and close the mold at the appropriate time in the molding cycle. The clamp unit also takes up the pressure applied to the plastic being injected by the injection unit during the injection part of the molding cycle. To oppose the injection pressure necessary to deliver the highly viscous melt to the mold requires a significant amount of force. Without adequate force, the mold would simply open at its parting line and allow the molten material to escape. The result can be a reject part, or a mess which would require down time for clean up, and even more important, it could result in personal injury to the operator or other person in the vicinity.