Preparation for Operation on Toshiba Injection Molding Machines

2.1 Precautions for Initial Power ON

Check the following before turning the power on for the first time.

1) Check if circuit breakers matched to the inverter are installed.

2) Check if the power and earth lines are securely connected.

If three phases (R, S, T) of power input are reversed, the mold thickness setter and injection unit will move to the wrong direction possibly causing an unexpected accident or breakage of the mechanism.

3) Check the cooling water line for a secure connection or no leakage.

4) Check if covers are securely attached.

5) Check if peripheral equipment is securely connected.

6) Check if the installation space around the machine is ample.

7) Check if the machine area is clean and free of unnecessary items, and tools and materials are set in places.

2.2 Inspection Prior to Starting Operation

[1] Cooling water checkCheck that cooling water is flowing under the hopper by observing the flow checker located on the non-operation side of the machine.

2.3 Starting the Machine

[1] Power ON

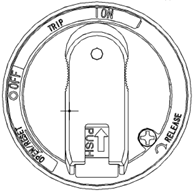

Turn the handle of main breaker (NFB) on the injection side of the control cabinet to [ON].

NOTES:

1. Turn OFF the power of machine with the main circuit breaker.

2. Turn the main breaker ON/OFF with your right hand while securely keeping your left hand off instruments or the machine body.

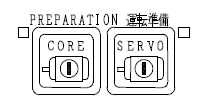

3. Press [SERVO] of the PREPARATION button to turn off the servomotor before turning the main breaker OFF.

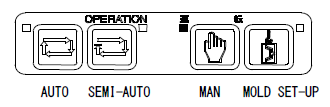

Press [MAN] of the OPERATION selector button on the operation controller.

[3] Preparation for operation

[3] Preparation for operationPress [SERVO] of the PREPARATION button on the operation controller to turn on the servomotor.

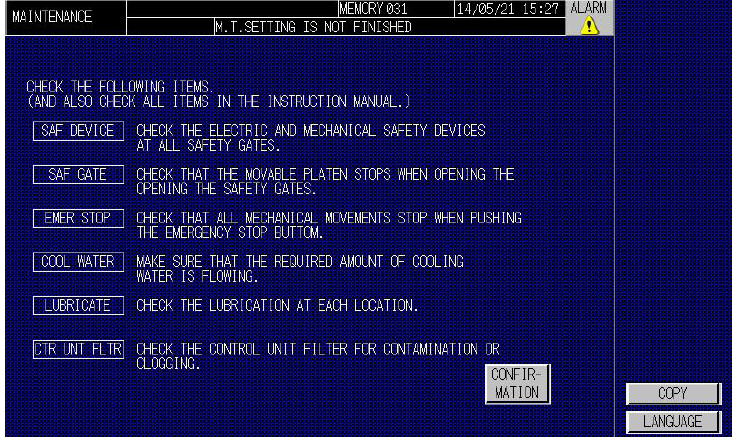

[4] Check at startup

[4] Check at startupAt power on the [MAINTENANCE] screen is displayed. Follow the procedure of the screen for inspection. Touch [CONFIRMATION] when checking is completed.