Precautions for Injection of Toshiba Injection Molding Machines

(1) Purging

During purging, such as when starting and changing molding material, perform injection by lowering injection speed and closing the purge shield to prevent decomposed resin from dispersing. During operation, stay away from the nozzle. Resin might emerge from the nozzle due to insufficient drying or deterioration, depending on the material. For your safety, wear proper protective gears when carry out purging.

(2) Removing the dripping resin from the nozzle

Never remove dripping resin from the nozzle when it is advancing.

(3) Approaching the nozzle tip

Keep your hands and face away from the nozzle tip during and after barrel temperature rise. Gas pressure can cause melted resin to gush out even when it is not injected.

(4) Never touch the nozzle, barrel and barrel heater cover since they have hot surface under

high voltage.

(5) Turn off the power and measure voltage at the working point to check that power is OFF before servicing electric parts and wiring such as heater or thermocouple.

(6) During operation, do not put your hands into the machine from the top or through the injection cover. Never touch moving parts of the machine.

(7) Do not operate the machine with the purge shield, injection cover or heater cover left removed.

(8) Removing the nozzle and end cap

Moreover securely turn off the power before removing the nozzle and end cap. Use only nozzles, plasticizing components, heaters, and bolts to mount them that are defined in our specifications.

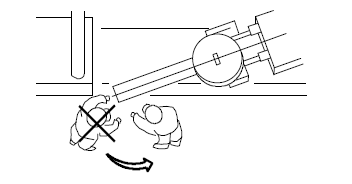

(9) Screw extracting

Turn off the power switch before removing the screw. Do not stand in the screw removal direction, in order to avoid injury if the screw jumps out.

(10) Inspecting and cleaning the hopper

Wear face, hand and arm protectors when inspecting and cleaning the hopper. Melted resin or gasses may gush out.

(11) Clearance of a blockage at hopper throat

Turn off the power and take out all material inside the hopper. Wear face, hand and arm protectors and remove the hopper and the hopper throat guard from the machine. Take away the blockage at feed throat by using a vacuume cleaner and a stick. Refit the hopper and the hopper throat guard correctly before restarting the machine.

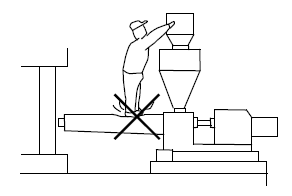

(12) Do not operate the machine with the hopper removed. Avoid putting your hands into the

hopper opening in operation.

(13) Check that the setting of barrel temperature is proper. Excessive temperature may

decompose melted resin and decomposed gas could gush out. The maximum allowable temperature for the plasticizing device is 500 °C (932 °F). However, only temperature up to 400 °C (752 °F) can be set as the maximum temperature under the standard specification.

(14) Removing the vented up resin

In the vented type injection molding machine, vented up resin should not be removed during screw rotation or injection. Melted resin or gassed may gush out while vented resin is being removed, or when the vent port is inspected. Be sure to wear a face protector.

(15) Do not make a step on the barrel heater

cover or injection unit cover. The barrel heater cover is designed to prevent burns and electric shock. If the cover is damaged, it can be extremely dangerous. There are no designated standing positions on the machine. Therefore use appropriate step ladders for access to the hopper or robot.

(16) Purging after operation

Thermal resin such as polyvinyl chloride or polyacetal, which are likely to thermally

decompose, must be purged after completion of production operation, and must be

replaced with stable resin, such as polyethylene.