Precautions for Clamping of Toshiba Injection Molding Machines

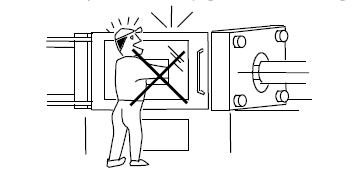

(1) Safety gate damage

Damages to the transparent panel of the safety gate require immediate repair. Never remove molded products from a hole. Be sure to open the safety gate before taking out molded products.

(2) During machine operation, never put your hands into the injection molding machine or around a safety gate. Never touch moving parts of the injection molding machine.

(3) Do not operate the machine with safety gates, safety guards, or safety devices left removed.

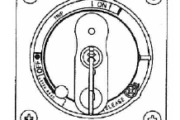

(4) Securely turn off the power and check that the ejector is located at the retract limit and core at the out limit before starting work on the mold.

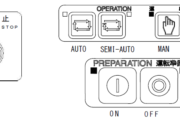

(5) Inspection for safety devices

Check that safety devices function securely at starting of work or changing of workers.

(6) Inspection for mold mounting bolts

Check the mold mounting bolts. If the mold is not properly secured, the mold may slide or fall during the injection molding process. Extreme caution should be exercised especially during NOZZLE CONTINUOUS ADVANCE.

Secure proper bolt size, number and threaded depth in sufficient consideration of maximum mold opening force and nozzle touch force.

The threaded depth should be more than 1.5 times the bolt diameter. Exercise care to ensure that mounting bolts are evenly fitted to the upper, lower, right and left sides of the mold. Periodically tighten mounting bolts since the bolts may become loose in operation.

Refer to the instruction manual “APPENDIX” to see proper mounting bolts and threaded

depth.

(7) Lifting the mold with crane for mold set-up

The mold should be kept lifted with a crane or some other means until clamping with installation bolts is completed. A mold not equipped with a locating ring may invite danger by falling if not clamped onto the platen with installation bolts.

(8) In case of taking out hot product from mold by hands, extreme caution should be exercised to avoid burn.

(9) Do not operate the machine with putting tools or products on the machine frame around liner guide. Otherwise it may cause machine damage.

(10) The height and distance of covers for mobile units have been designed in accordance with the safety standard to secure the safety zone.

Note that additional covers are optionally available on customer’s request.