Plastic Injection Blow Moulding Process

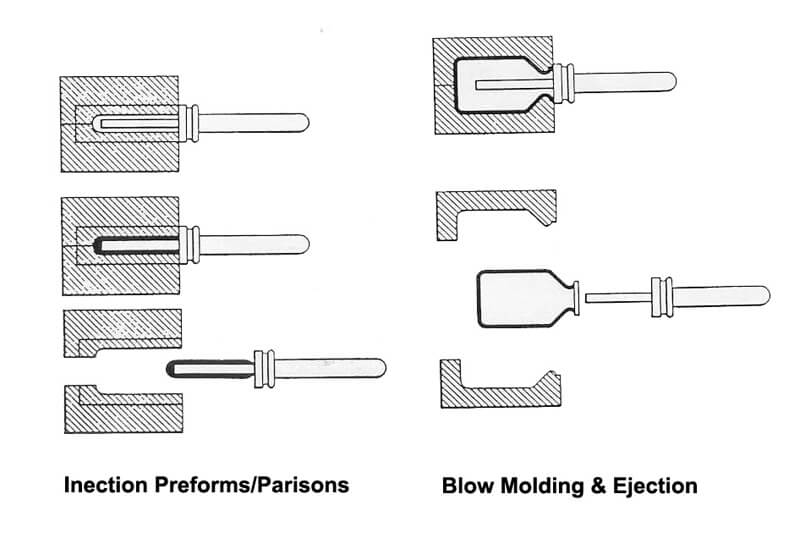

Injection blow moulding process can be separated as injection moulding process and blow moulding process.

1. Injection moulding process: The injection molding is finished by an injection molding unit or machine. In this process we will produce a semi-finished product called preform or parison. Raw material is melt in a barrel and feed to the nozzles, injection to a injection mold, then we have the perform with kinds of bottle neck types.

2. Blow Moulding process: The blow molding is we put the performs or parisons to a blowing mold and use high pressure air to blow it up as a bottles or other hollowed containers.

Now you know exactly two steps injection blow moulding process. And you can see we will need two main machines: injection molding machine and blow molding machine. It is a bit comples to produce a bottle or container but running very fast and have huge output capacity. This two step injection molding process is mostly use for PET bottles and containers manufacturing (Water bottles, soft drink bottles, edible oil bottles, cosmetic spray bottles, jar for foods, etc) .

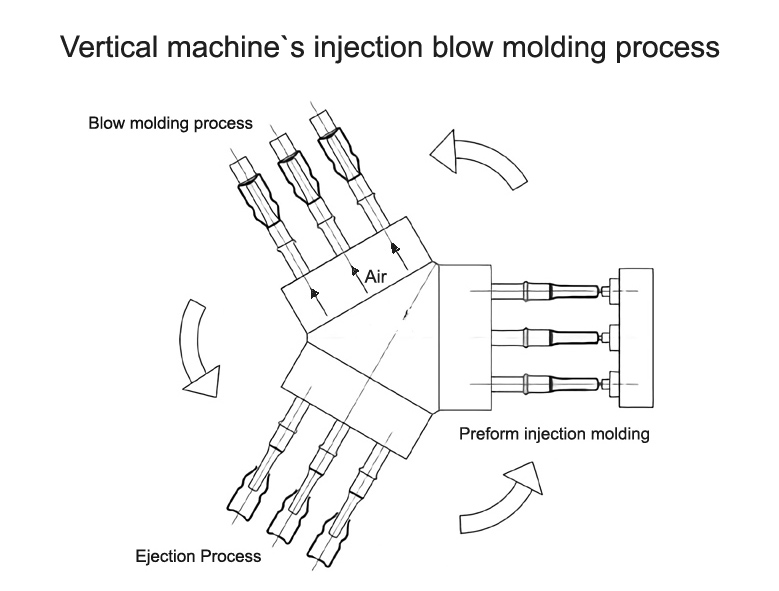

There is a simple one step injection blow molding process as well, it combined the two steps in one machine. This machine will finished the injection molding and blow molding until we have the final products.

Below picture shows the vertical injection stretch blow molding machine running the injection blow molding process:

And there are horizontal injection blow molding machines can finish the injection blow molding process as well:

Difference between one step and two steps injection blow molding process:

| Molding Method | Moulding Process | Required equipment | Main Molding Machines |

|---|---|---|---|

| One step injection blow molding | Continue process from Material to Preform to Products | Preform injection unit, temperature ADJUSTED unit, stretch blow unit, ejection unit |

All process done on one machine |

| two steps injection blow molding | Seperated processes: injection preforme and blowing process. | Injection molding machine, preform transfer machine, preform sorting machine, preform loading machine, REHEAT unit, stretch blow unit, ejection unit |

Injection molding machine, stretch blow molding machine and other auxiliary equipment |

So you can learn from above table: Preforms whether cooled and reheat to be blown is the evident difference between two steps and one step injection blow molding.

Materials can be run for injection blow molding process:

| Plastics` Full Name | Plastics` Short Name |

|---|---|

| Polyethylene (Low Density) | LDPE, LLDPE |

| Polyethylene (High Density) | HDPE |

| Polypropylene | PP |

| Polyethylene – Terephthalate | PET |

| Polyvinyl chloride | PVC |

By read here, you should have known a lot and complete understand the injection blow moulding process. If not or have any questions, please feel free to leave your comment below. We will back to you once we seen it.