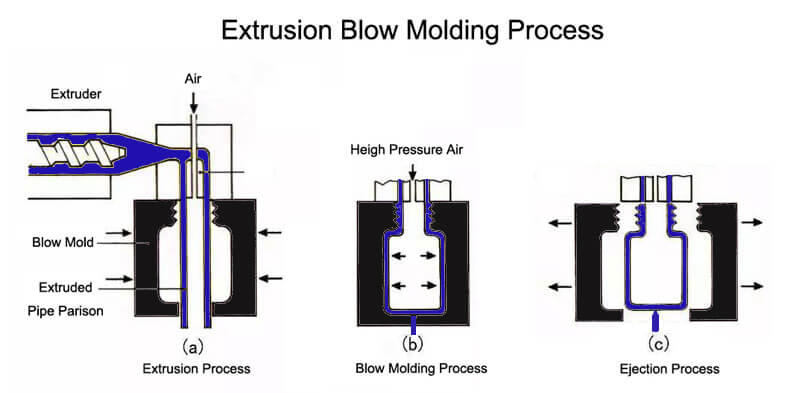

Plastic Extrusion Blow Molding Process

Extrusion blow moulding process is the largest and the earliest type of blow molding method. It is used to create hollow plastic products.

It is suitable for the blow molding of polymers such as PE, PP, PVC, thermoplastic engineering plastics and thermoplastic elastomers, and various plastic blends. Used to produce packaging containers, storage tanks and other industrial parts.

Extrusion blow molding process is start from the material is melted and plasticized in the barrel. And then extruded from the head of the extruder with conventional downward tube. When the hube parison reaches a predetermined length, a section of tube embryo is intercepted and placed in the blow mold while still hot. The mould is closed catching and holding the neck end open and pinching the bottom end closed. the compressed air blown into the parison through the air blowing nozzle The tube prison will be precisely inflated as the desired shape of the mold cavity. After the mould is completely cooled and then the mold can be opened to take out the product.

Advantage and disadvantage of extrusion blow moulding process:

| Advantage of extrusion blow moulding process | Disadvantage of extrusion blow moulding process |

|---|---|

|

The manufacturing cost is low; Can produce multiple layers; Can produce thin-walled and complex containers; Product volume ranges is up to 3000L. |

Have flashing at both side of container Thread size is unstable and leakproofness is poor; A bit hard to run automatic production for some products; Cycle time is a bit long and efficiency is a bit low; Have parking line on the neck and bottom. |

However, the extrusion blow molding process has obvious advantages in the production of thin-walled products, complex shapes of tubes or bottles by the advantage of the two technologies: coreless design and wall thickness controlled by parison controller.

The coreless design shines in the field of household cosmetics. Taking the common large-volume daily chemical bottle as an example,

customers will prefer products with handles due to the large size and heavy weight of the bottle. The coreless design does not need to

consider the problem of demolding and clamping, and can produce containers with handle structures, even foldable containers with complex structures, etc.

The parison wall thickness controller can adjust the wall thickness distribution of the parison according to the parison blow-up ratio of each part during the parison forming stage, and blow-mold to produce a uniform thickness product.

Taking the automobile industry parts as an example, automobile door panels, roof panels, and seamless door handles commonly used in high-end cars produced by the extrusion blow molding process are thin and light but high in strength, reducing fuel consumption and manufacturing costs. Therefore, more and more auto parts adopt extrusion blow molding technology, such as the production of fuel tanks and various pipe fittings.