PET Preform Making Machine is an optimized injection molding machine for PET preforms injection molding. It is the most important PET machine in PET bottle preform manufacturing process. Or even in whole PET bottle production process. Almost all the PET injection moulding machine is dedicated designed according to the PET materials characteristics. An professional PET preform injection moulding machine should be optimized the injection unit (Screw,barrel, heating, etc), Clamping Unit ( Clamping platen, clamping force, Ejectors, etc), and the machine`s frame & controls.

- Low-temperature Plasticizing System

- Eco-friendly and Energy-saving

- Lower Hydraulic System Pressure

- Shorter System Response Speed

- Faster Injection / Shot Speed

- Lower Molecular Internal Stress

- Higher Tenacity & toughness Products

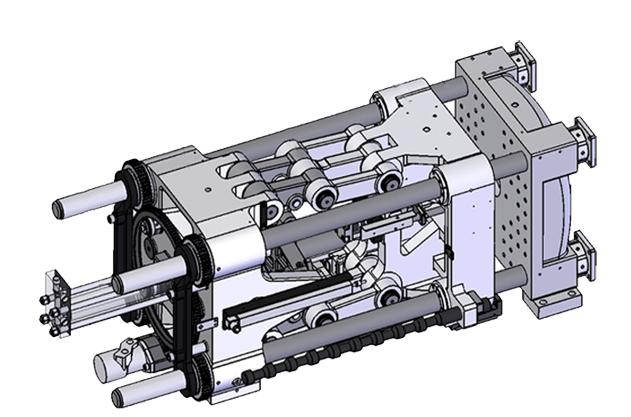

Optimized Injection Unit for PET Preform Making Machine

- The Diamer of the Screw is big as the shoot weight is very big comparing to other materials.

- L/D is mostly 22,the feed length L1=50-60%,transition length L2=20-30%, Metering Length L3=20-30%.

- Low shear, low compression ratio screw is a most collection. The compression ratio ε=1.8-2.2. Raw materials will become discolored or opaque due to excessive shear heat. h3=0.09-0.10D .

- The mixing element is more complex and very very important. As most PET bottles require high transparency, high color uniformity, high gloss surface. Especially for PET cosmetic bottles.

- Bigger hole of injection nozzle for PET material injection.

- A longer screw and barrel is need due bigger L/D ratio and adding longer mixing element. A support construction is in need to avoid the barrel is getting bended after years running.

- Nano-heating band is also an important part. As you will run dozen tons of PET material and heated it up to 190 degree from your in-house temperature. It can help a lot for energy saving.

- Four or above stages precise temperature PID control for barrel.