Nozzle Selection, Assembly and Disassembly of Toshiba Injection Molding Machines

(1) Nozzle selection of Toshiba Injection Molding Machines

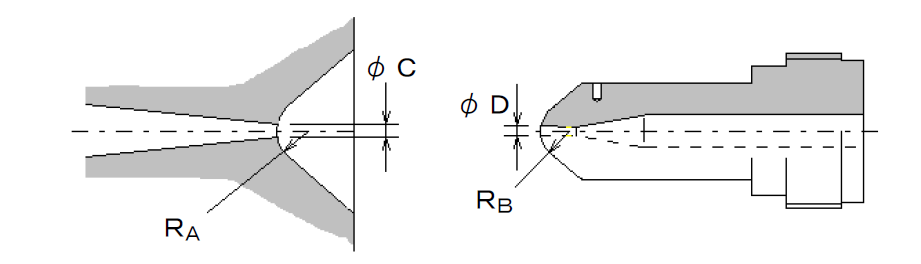

In general, select a nozzle with the curvature radius (RB) of nozzle tip smaller by 1 mm (0.04 in) than the curvature radius (RA) of sprue bush, and nozzle diameter (fD) smaller by 0.5 mm (0.02 in) than the diameter (fC) of sprue bush.

Be sure to use only the nozzle and set bolts specified by us.

(2) Nozzle assembly and disassembling of Toshiba Injection Molding Machines

When disassembling and assembling the nozzle, handle the nozzle, barrel and heater cover with extreme care since hot. Removing the nozzle or end cap with resin left inside the barrel may cause resin to gush out. Close the hopper shutter and repeat charge and injection to thoroughly purge resin out of the barrel before disassembly work. Be sure to wear proper protection tools before working.

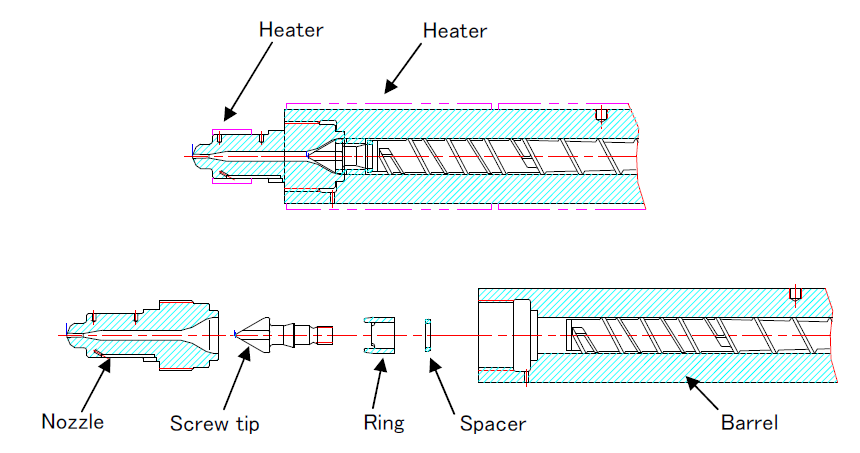

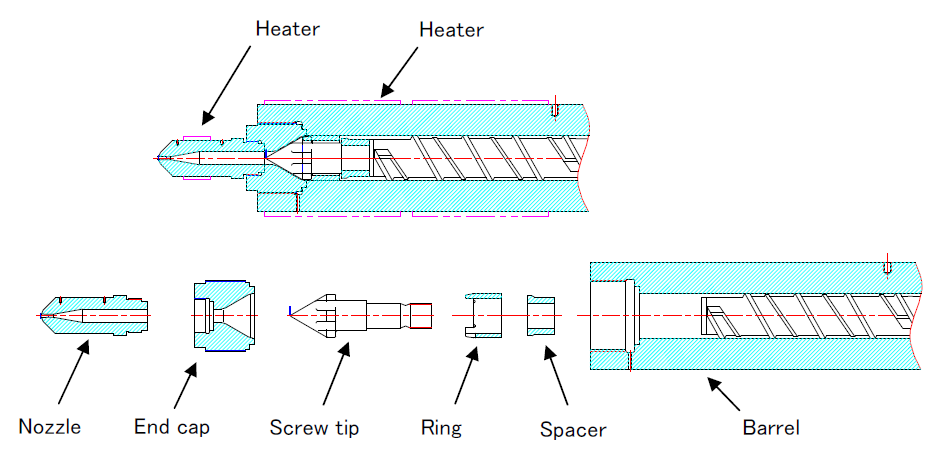

Follow the procedure below to assemble or disassemble the nozzle. Refer to the construction drawing of the plasticizing parts containing the nozzle on the next page. Refer to STE 83543, INJECTION MOLDING MACHINE INSTRUCTION MANUAL (MAINTENANCE AND INSPECTION) for the replacement of the screw and barrel.

1) Close the hopper shutter and repeat charge and injection to thoroughly purge resin out of the barrel. Replace the material with purge material such as PS or PE as required to discharge resin completely.

2) Continuously press [RETRACT] of the NOZZLE button to move the injection unit to the open limit.

3) Press [INJ] of the SCREW button to move the screw to the advance limit.

4) Turn off the power of the machine.

5) Remove nozzle heaters and nozzle thermocouples.

6) Set the attached double offset wrench on the nozzle to give impact to loosen the thread and remove the nozzle. The nozzle is given with right-hand thread.

7) Remove the resin remaining on the thread or sealing face of the nozzle or end cap (or

barrel).

8) When mounting the nozzle, apply metal lubricant (LUBE-EKS P9, OMEGA 99 or equivalent) to the thread of nozzle, and attach the nozzle to end cap (or barrel) lightly.

9) Attach nozzle heaters and nozzle thermocouples.

10) Turn on the power of the machine.

11) Turn on heaters. When the barrel and nozzle reaches the same temperature after heating, tighten the nozzle again.

Construction drawing of i2Y and smaller plasticizing parts

Construction drawing of i2A-i8 plasticizing parts