Monthly Maintenance Checklist for Injection Molding Machines

| Item | Inspection Procedure | Check/Measure | |

|---|---|---|---|

| Safety gate on operation side | Grip the knob of the safety gate, and shake it lightly back and forth, and up and down. | Investigate and eliminate the cause if abnormally plays. | |

| Safety gate on non-operation side | Push the transparent panel of the safety gate lightly. | Check that the transparent panel is in close contact with the gate. | |

| Safety gate on non-operation side | Open and close the safety gate. | Check that there exists no abnormal play or wearing between the rail and safety gate roller. If worn, replace the roller. Check that the safety gate does not derail due to loosening or breakage of the rail support bracket. |

|

| Safety gate limit switch | a. Inspect set bolts for loosening. b. Inspect rollers and levers for breakage. c. Inspect the cam installed on the safety gate for deformation. |

a. Tighten set bolts if loose. b. Replace them if broken. c. Correct it if deformed. |

|

| Safety gate rail and roller | a. Inspect set bolts of rail clamp bracket for loosening. b. Inspect set bolts of safety gate roller for loosening. |

a. Tighten set bolts if loose. b. Tighten set bolts if loose. |

|

| Set bolts Barrel | Inspect barrel set bolts for loosening with a bar wrench. | Tighten set bolts. | |

| Mold fixing bolts | Visually inspect fixing bolts for breakage. | Check set bolts for being cracked, crushed threads, or damaging on the wrench set portion. Replace bolts if broken. |

|

| Mold thickness setter Clamp bolts | Inspect gear clamp bolts of mold thickness setter for play or loosening. | Tighten clamp bolts if loose. | |

| Load cell in Injection unit | Turn on the power and check the value of [INJ PRESS] on INJECTION screen | Refer to section 6-6 Inspection for Load Cell. | |

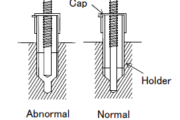

| Screw End cap | Remove the end cap to inspect the end and inner faces for wearing or any abnormality. | Check if these parts are usable depending on the worn status. Change these with spare parts if not usable.Contact us for ordering spare parts, if not stocked. | |

| Screw tip | Remove the screw tip to inspect the inside for wearing or any abnormality. | Check if these parts are usable depending on the worn status. Change these with spare parts if not usable.Contact us for ordering spare parts, if not stocked. | |

| Clamp ball screw Eject ball screw Injection ball screw Nozzle touch ball screw Other points | Remove the covers of clamp unit, injection unit and nozzle touch mechanism to visually inspect lubrication status (insufficient lubrication, scratches, fouling or foreign matters). | If fouled excessively, clean the lubrication area. For inspection method, refer to section 6-3 Inspection for Lubrication. | |

| Control cabinet / Supply voltage | Measure supply voltage by using a voltmeter. | Check that supply voltage is within ±10 % range of rated voltage. | |

| Electric wiring / Control cabinet and terminal box | Inspect loose bolts on the connections of terminal block and electric equipment. DANGER: Securely turn off the power and measure voltage at inspection points to check power off before inspection. |

Tighten bolts if loose. | |

| Air filter / Control cabinet and operating panel (model with air filter) | Remove the air filter cover to check if the filter is fouled. | If fouled, remove the filter for cleaning by water washing or vacuuming. Dry sufficiently after water washing. Replace the filter if fouled excessively. |

|

| Cleaning the machine | 1) If dents exist on tie rods or sliding surface, flatten them with a fine oil stone. 2) Remove excessive grease. Metal and other dust are easily caught in grease, lowering machine accuracy and causing quicker wearing. Never use solvent for this purpose. 3) Remove pellet overflow around the hopper. |

||

| * By TOSHIBA MACHINE CO.,LTD. | |||