Modification of Barrel Temperature control on Injection Molding Machines

[To the users of the IS-E, IS-F, IS-G, IS-GN, and EC series]

The temperature control structure has been partially modified for the EC-N series and the subsequent series (EC-NII, EC-S/SX and EC-SXⅡ).

Understand the following change and different temperature distribution before attempting to adjust the temperature conditions.

[Precautions for Barrel Temperature (i1, i1.5, i2)]

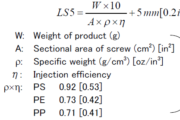

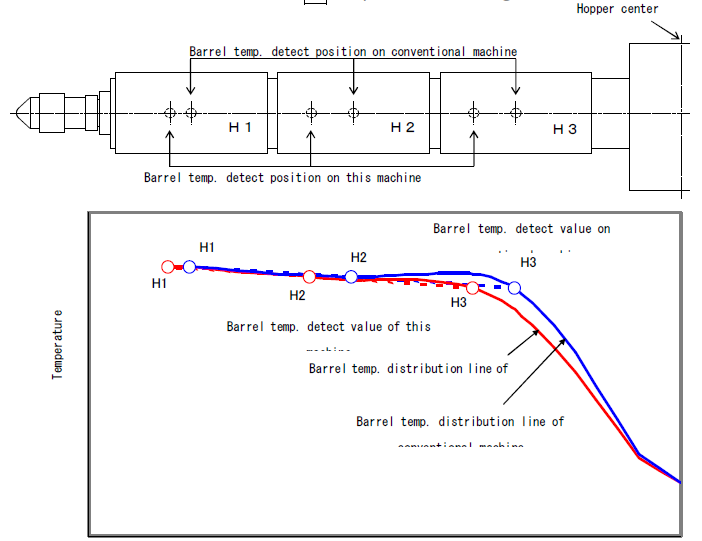

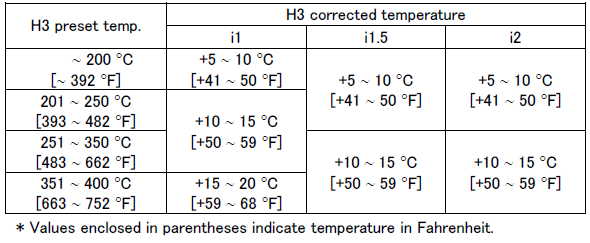

To attain smooth barrel temperature distribution, this machine has the barrel temperature detect position changed from that of conventional machine as shown in the figure below. This change results in no change to molding conditions. When using resin with high melting latent heat (for example, olefine-based resin) or it is necessary to attain barrel temperature distribution close to that in production with a larger charge stroke of conventional machine, however, we recommend to correct H3 temperature according to the table below.

[Precautions for Hopper Throat Temperature (i1, i1.5, i2]

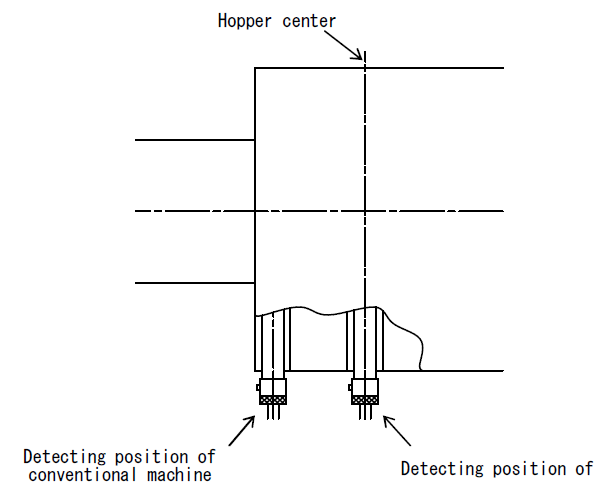

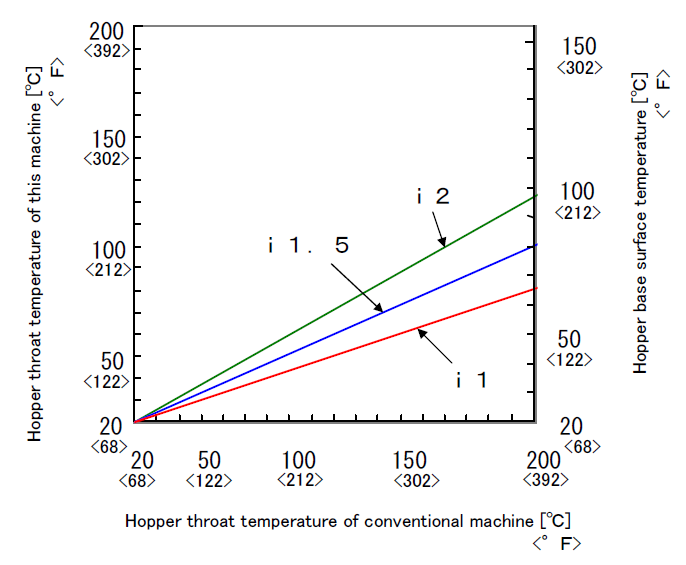

Note that since this machine has the hopper throat temperature changed from the conventional machine, its detect position is different from that of the conventional machine. To change the detecting value of the conventional machine to that of this machine, refer to the diagram below.

[To the users of the IS-E, IS-F, IS-G, IS-GN, EC, EC-N, EC-NII and EC-S/SX series]

The temperature control structure has been partially modified for the EC-SXII series. Understand the following change and different temperature distribution before attempting to adjust the temperature conditions.

[Precautions for Barrel Temperature (i3 to i17)]

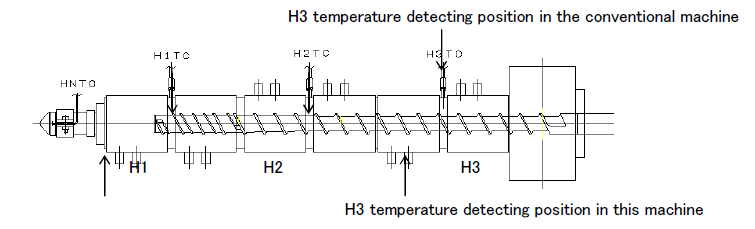

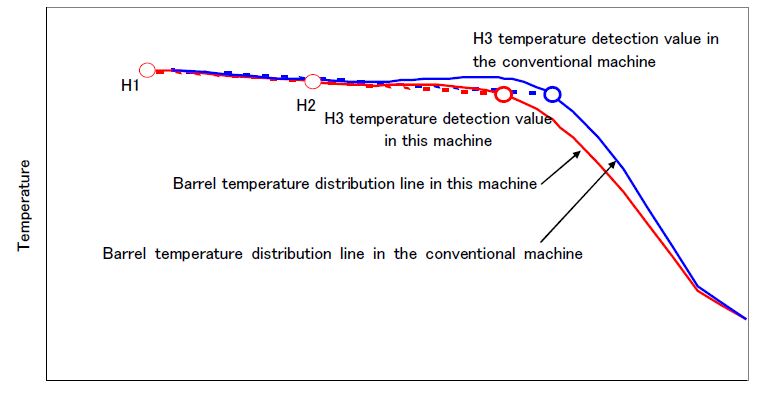

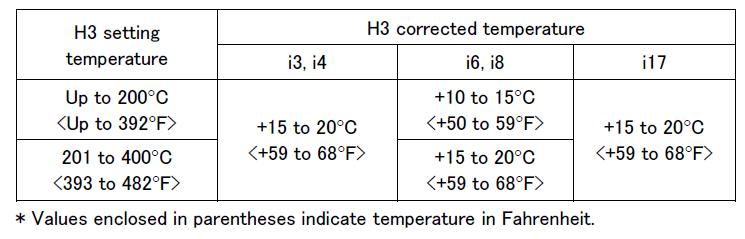

To attain smooth barrel temperature distribution, this machine has the barrel temperature detect position changed from that of conventional machine as shown in the figure below. This change results in no change to molding conditions. When using resin with high melting latent heat (for example, olefine-based resin) or it is necessary to attain barrel temperature distribution close to that in production with a larger charge stroke of conventional machine, however, we recommend to correct H3 temperature according to the table below.

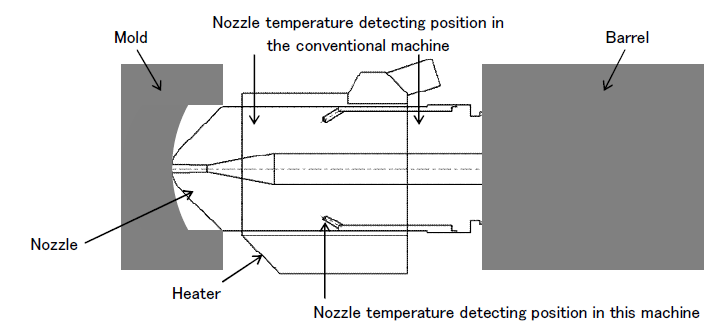

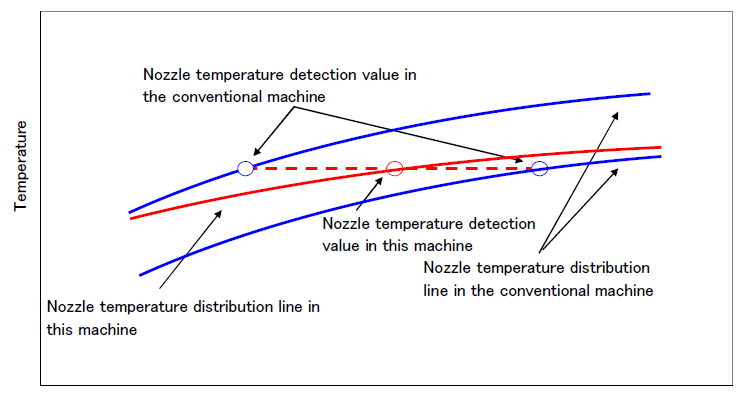

[Precautions for nozzle Temperature (i2 to i17)]

To attain smooth nozzle temperature distribution, this machine has the nozzle temperature detect position changed from that of conventional machine as shown in the figure below. This change results in no change to molding conditions. However, we recommend that the HEN and HN temperatures be adjusted by about ±10C<±18F> if it is necessary to get the nozzle temperature distribution close to that of the conventional machine in the case of molding where a cold slag or cobwebbing may occur to the resin (e.g., nylon) or where the molding cycle is longer, the mold temperature is lower or there is a greater difference between the barrel temperature and nozzle temperature.