Abstract: Optimal design of plastic injection molding parameters are discussed concerning preheating temperature, stove temperature, mold temperature, pressure oil temperature, clamping force, mold filling speed, filling pressure, dwell time, dwell presure, screw speed, pressure reliefback pressure. Norial problems and quality faults in plastic injection are also analyzed in detail.

Injection molding refers to an operation process in which a resin is heated and melted, uniformly mixed with other additives, and then injected into a mold to be cooled and solidified to obtain a product having a desired shape. In order to allow the molten material to sufficiently flow into the corners of the mold cavity to obtain a product having a full shape, no wrinkles on the surface, and no voids inside, it is necessary to apply a high pressure to the melt at the time of molding. For a certain plastic parts, when the appropriate plastic varieties, molding methods and equipment are selected, and the reasonable molding process and mold structure are designed, in the production, the selection and control of the process conditions is to ensure the smooth formation and the quality of the plastic parts. The essential. A reasonable injection molding process should ensure product quality in an economical and efficient manner.

The entire injection molding process includes: mold closing, mold locking, cavity filling, plastic parts holding, mold cooling, mold separation, product demoulding and injection molding delay. In these processes, the setting of various parameters is extremely important. The main process parameters are temperature, pressure and speed.

1 main injection parameter analysis settings

(1) Preheating temperature of plastic: Most of the plastic is in front of the shooting cylinder.There is often a preheat treatment process. Its purpose is two-fold: one is to heat and dry the plastic; the other is to make the melt more evenly enter the shooting tank. When plastic is injected, it generally requires that the water absorption rate does not exceed 0.1%. When the requirements are strict, it often does not exceed 0.04%. This requires the plastic to have a preheating drying process before injection molding. In addition, the preheating temperature of the plastic before entering the shooting tank is also important for the uniformity of the melt and the weight and dimensional stability of the finished product. When changing the preheating temperature of the plastic, the following two phenomena can be found:

a. Injection cycle The time for resetting the inner screw also changes, and the reset time becomes stable as the temperature increases.

b. After the plastic part is filled and saturated, the volume of plastic (padding) remaining before the screw becomes stable.

Therefore, it should be noted that the preheating of the plastic before injection molding is important, and the preheating temperature and drying time of some common plastics are provided in the attached table below.

(2) Barrel temperature (melting temperature): The plastic enters the shooting cylinder and can be injection molded by heating to reach the melting temperature. The choice of barrel temperature should ensure that plastic plasticization is good, and the injection can be smoothly achieved without causing plastic decomposition. In general, the higher the temperature, the better the fluidity of the plastic, but the more easily it decomposes. For amorphous plastics, the maximum temperature at the end of the barrel should be higher than the flow temperature, and for crystalline plastics should be higher than the melting point, but must be lower than the decomposition temperature of the plastic, otherwise it will cause the melt to decompose. Different types of injection molding machines use different plastics in the barrel. For the plunger type injection molding machine, the temperature of the barrel should be higher, so that the inner and outer layers of the plastic are evenly heated. For the screw type injection molding machine, due to the screw rotation and stirring, the plastic is subjected to high shear force and frictional heat generation, so the barrel temperature selection Can be lower.

In addition, in the injection molding industry, the method of “high-temperature injection thin wall, low temperature injection thick wall” is usually applied. Because the cavity of the thin-walled plastic part is narrow, the melt injection resistance is large, and the cooling is fast, the temperature of the barrel should be selected to increase the fluidity of the plastic to achieve the purpose of full filling. The higher the temperature of the melt, the longer the residence time in the shot cylinder, the easier the plastic will decompose. However, if the nozzle temperature is too high, the “casting phenomenon” will occur. If the nozzle temperature is too low, the melt will prematurely condense and the nozzle will be blocked.

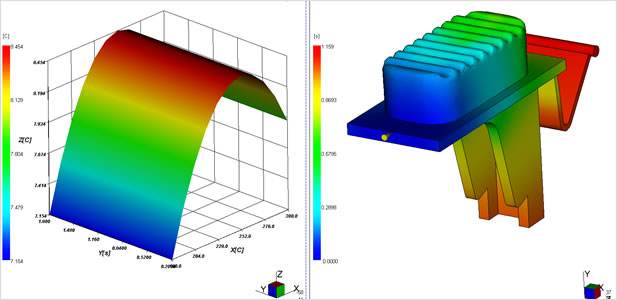

(3) Mold temperature: It has been proved that when the temperature of the mold is increased, the total shrinkage of the plastic part will increase. However, if the pressure or the rate of fire injection can be matched, the dimensionally stable product can usually be produced because of the mold temperature. The improvement is beneficial to the filling of the molten plastic, but correspondingly increases the injection cycle time. There are two main types of mold temperature control, one is heating with electric heating coil or electric heating rod, and the other is controlling the mold temperature by the temperature of the coolant in the mold cooling system and the flow rate of the coolant. It can also use a cooling machine or a mold. The temperature machine is controlled.

(4) Temperature of the pressure oil: One of the factors that causes the change of the mold filling is the pressure oil temperature of the injection molding machine, which can significantly affect the performance parameters of the injection molding machine. Therefore, the operating oil temperature of the injection molding machine is generally 40~50 °C.

(5) Clamping force: When the mold is designed, the design value of the clamping force has been obtained. According to the theoretical calculation method, the clamping force is: F≥Pm(nA+A2). Where: F a clamping force (N); A1, A2- are the projected area of the product and the casting system on the parting surface (mm2); Pm—the average pressure (MPa) of the plastic melt in the cavity.

The injection molding machine injects the plastic melt through the nozzle, the flow channel and the gate to reach the cavity, which will cause pressure loss. The average pressure in the general cavity is only 40%~50% of the injection pressure, ie Pm=(40%~50 %)Po, Po is the injection pressure.

In actual production, the clamping force must be set on the injection molding machine before injection molding. The clamping force is different for different molds. When setting the clamping force, the larger the clamping force, the better, but the size of the mold and the injection molding machine, as well as the design form of the mold and product. From the economic and technical analysis, the value of the clamping force should be as small as possible, but it must meet the needs of product injection molding. For example, under the condition of low clamping force, the wear of the injection molding machine and the mold can be reduced, and the energy consumption and maintenance cost can be reduced. Moreover, the small clamping force can also improve the exhaust capacity and make the filling of the mold easier. Accurately adjust the clamping force. The following methods can be used to adjust the maximum clamping force that the mold can withstand and produce the product. Then, the clamping force is gradually reduced by the difference of 5 tons, and each clamping force is measured. Under the weight of the produced product, draw a graph to find the best clamping force parameters.

(6) The mold filling speed (also known as the injection speed) is the linear velocity at which the melt is injected into the cavity. During the filling phase of the injection molding, the firing rate of the melt must be controlled to achieve the best performance of the product.

(7) Mold filling pressure (injection pressure): In order to ensure that the injection speed of the injection molding machine reaches and maintains the required value, the injection pressure is required to be sufficient. The size depends on the type of plastic, the mold structure, the structure of the plastic part and the associated process conditions, especially the structure and dimensions of the gating system.

(8) The holding pressure refers to the pressure used when the cavity is just filled. Its function is to make the melt in the cavity cool and shape under pressure, so that the appearance and dimensional tolerance of the product can be guaranteed. The final shape of the plastic part depends largely on the pressure of the pressure. And the length of time for holding pressure. In general injection molding, when the cavity is filled to 95%~98%, it is changed to the pressure holding stage.

Generally speaking, the holding pressure is high, and a plastic part with high density, small dimensional shrinkage and good mechanical properties can be obtained, but if the holding pressure is too high, the product may have burrs or large residual deformation, and sometimes Will affect the release of the product.

(9) The dwell time can be selected by the following method: firstly, the dwell time is set to zero, the dwell time is gradually increased by the difference of 0.5 s, and the plastic parts are injection molded, and the weight of each molded plastic part is recorded. Take out the graph and find the correct dwell time parameters.

(10) Setting of screw speed: When one injection and pressure keeping is completed, the screw starts to rotate and retreats. The rotational speed of the screw significantly affects the stability of the injection molding process and the amount of heat acting on the plastic. When the screw speed is high, the friction (shear) energy transmitted to the plastic increases the plasticizing efficiency, but at the same time increases the unevenness of the melt temperature, and may cause local overheating of the melt. On the contrary, the screw The lower the speed, the more uniform the temperature of the melt, but the production cycle may be prolonged. The speed range of the screw for common plastic injection is listed in the attached table.

(11) Clamping force mold filling speed Mold filling pressure holding pressure Pressure holding time: screw rotation speed setting screw retracting (retracting or depressurizing): screw retreating action is generated after screw rotation is completed, its main function is to prevent shooting The melt leakage of the nozzle avoids the use of a nozzle with a throttle. In addition, for some plastics (such as polyolefin, PET, etc.), the application of screw retraction can improve the stability of the injection process. In general, when the screw needs to be retracted, the value is in the range of 4 to 10 mm, but not all plastic production requires this action.

(12) Back pressure: When the screw rotates, the plasticized plastic is pushed forward by the screw and passes through the stop valve to reach the front of the screw. As the melt advances, the melt also produces a reaction force acting on the screw and the check valve, causing the screw to retreat so that more melt can be advanced. At this time, if the back pressure is adjusted, the cylinder has a certain pressure and then acts on the screw forward, providing the resistance of the screw to retreat. The greater the back pressure, the longer the screw reset time, and the pressure generated by the melt at the front end of the screw must be greater than the back pressure to allow the screw to retreat. It must be pointed out that not all injection molding production must use back pressure, but if back pressure is used, the plastic can be fully melted and evenly mixed, and has the following advantages:

1 It is good for the discharge of volatile gases in the melt;

2 Making the additament (such as toner, talcum powder, flame retardant, reinforcing agent, etc.) and the plastic mixture is more uniform;

3 Increase the friction of the plastic to make the plastic plasticization more uniform, to obtain accurate product control, the back pressure adjustment is not too large As long as the melt has proper uniformity, it can be plasticized and there is no air bubble.