How To Replace Heater Fuse in Injection Molding Machines

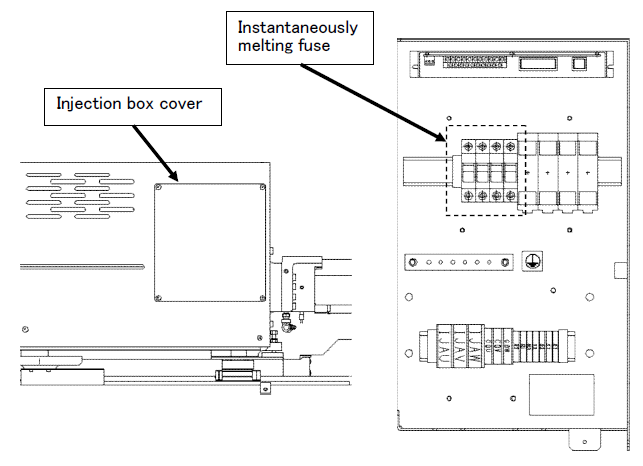

Since a triode AC switch (semiconductor) is used for the solid-state relay in the heater control circuit, a fuse for semiconductor protection (instantaneously melting fuse) is used to prevent overcurrent. The fuse, when required, must always be replaced with the same type and rating of the fuse.

Note that a normal fuse cannot protect the solid-state relay. Even if an instantaneously melting fuse is used, repeated fuse blowing due to short-circuits, etc. will deteriorate the semiconductor, possibly causing damage to the solid-state relay. Therefore, short-circuiting should be minimized.

There are instantaneously melting fuses in the Injection box of non-operation side.

Securely turn off the power and measure voltage at replacing points to check power off before replacing fuses.

By TOSHIBA MACHINE CO.,LTD.