How to Hang / Load TOSHIBA All-electric Injection Molding Machine

Work Procedure

1. Mechanical unit

(1) Check the foundation surface for unevenness.

(2) Remove the top cover from the safety gate. This cover is removed at a time of shipment from the factory.

(It is not attached to EC230SXⅡ)

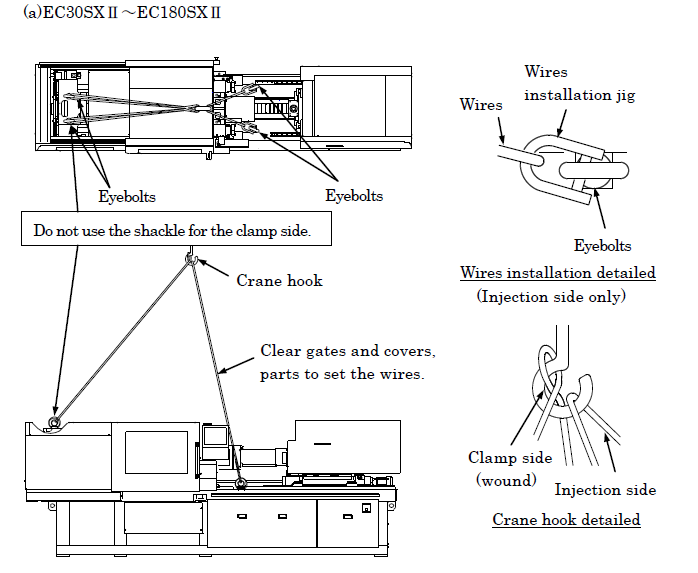

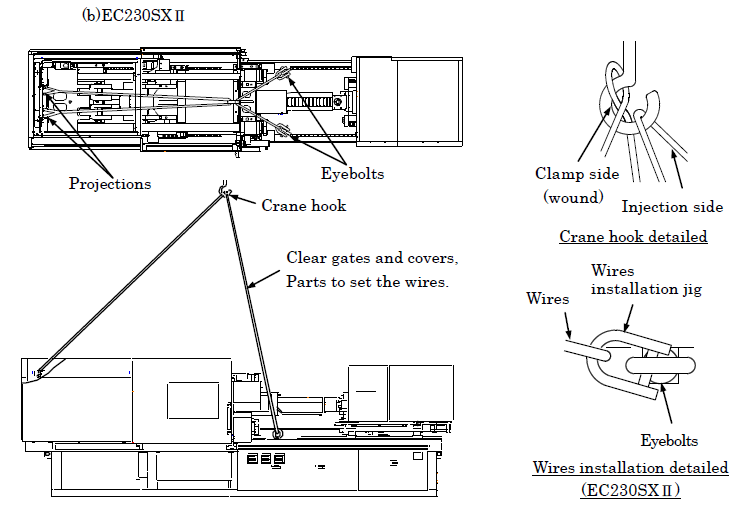

(3) Set eyebolts or lifting jig on the prescribed positions of the machine. Apply wires installation jig onto the eyebolts or lifting jig.

(4) EC30SXⅡ~EC180SXⅡ:Apply wires onto wires installation jig to unload the truck.

EC230SXⅡ:Apply wires onto wires installation jig and projection to unload the truck.

Refer to section 3-2 about machine weight.

Refer to section 3-3 when moving the machine by a forklift.

(5) Do not make a step on the oiling piping unit, when slinging work wire ropes.

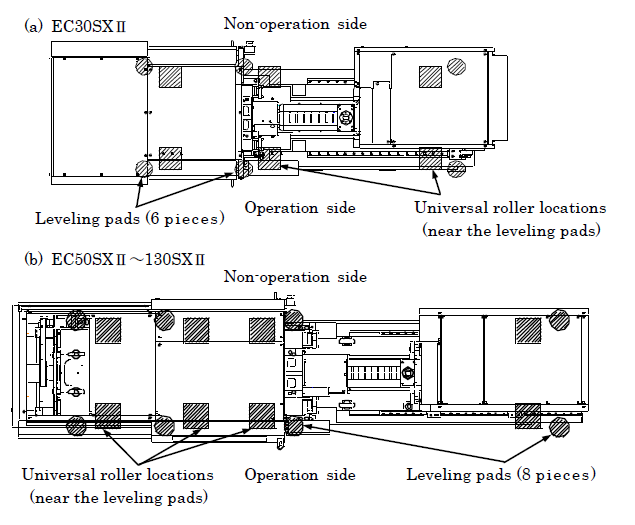

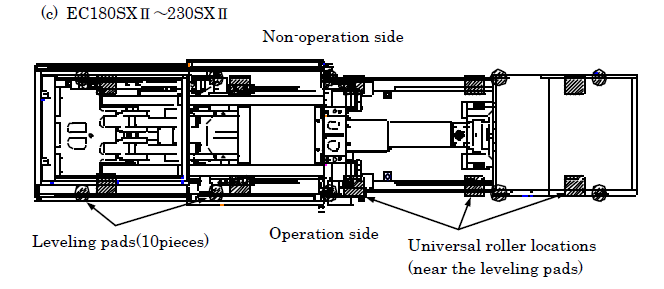

(6) Use universal rollers to locate the machine at the prescribed position.

(7) Use a crane or jack to lift the machine and install leveling pads.

(8) Fit the supplied top cover on safety gate. (It is not attached to EC230SXⅡ)

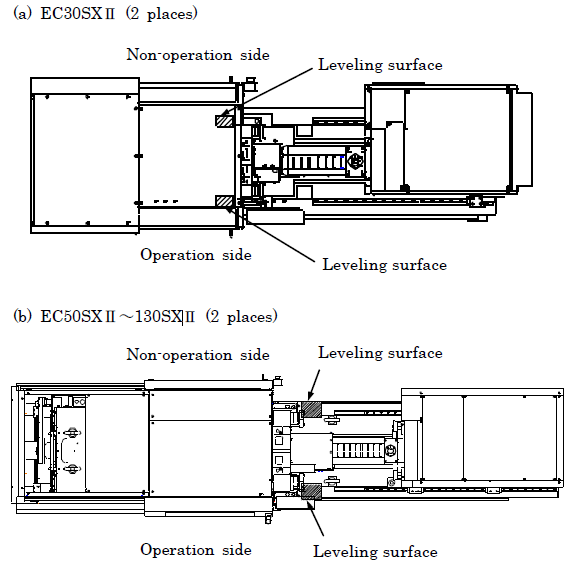

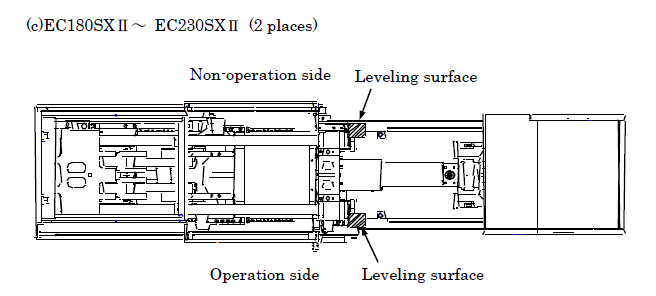

(9) Place a level measuring instrument on the leveling surface to secure level. (Allowance: within 0.20 mm/m)

(10) Secure the nozzle center by measuring the locating hole of the stationary platen

and nozzle hole. (Misalignment: within 0.1 mm)

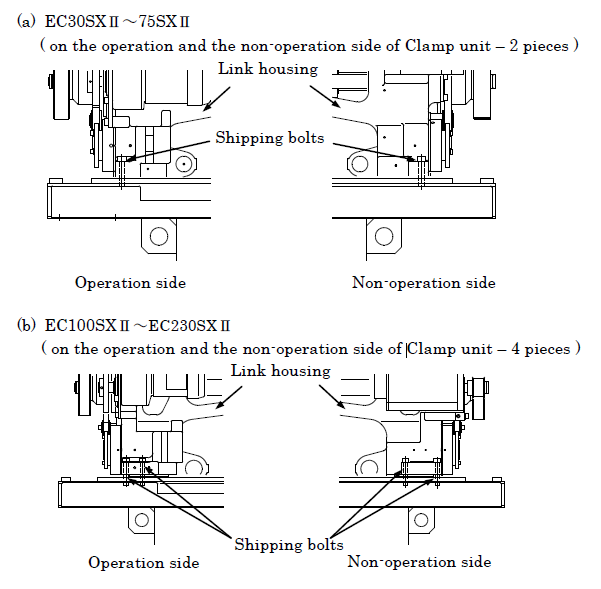

(11) Remove shipping bolts for the link housing

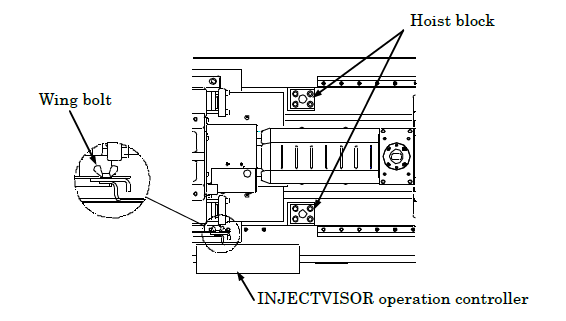

(12) In the case of EC30SXⅡ, remove hoist block on the frame and wing bolt on the INJECTVISOR operation controller.

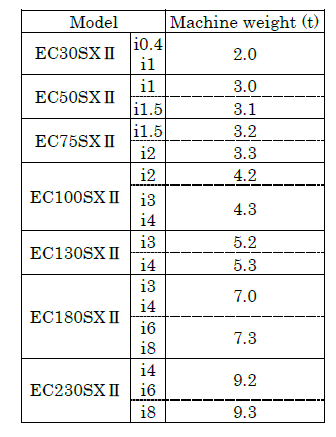

3-2 Machine weight

Refer to the following list for machine weight.

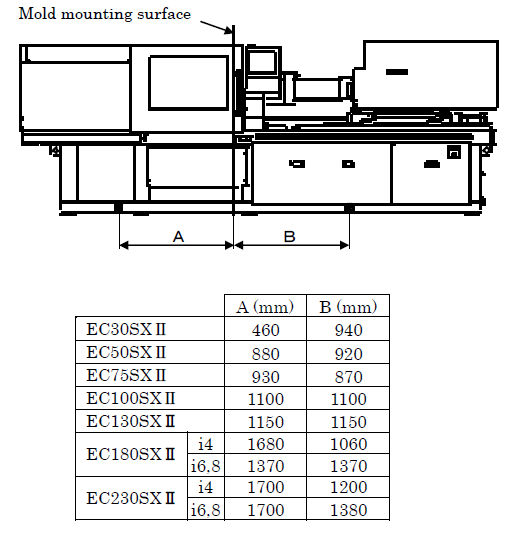

3-3 Li f t ing positions of forklift

When moving the machine by a forklift, set forks at A and B positions and lift the machine.

3-4 Electric parts and equipments

(1) Connection of power source

Observe the following precautions to connect the power source.

(a) Check for correct wiring since wrong connection may reverse motors. You

may check the wiring with direction of nozzle movement.

(b) Check terminal blocks and cable connectors of electric equipments for loose

bolts.

(2) Precautions (as per instruction manual)

(a) Grounding work

Complete grounding work. Installation grounding of resistance below RΩ.

R=100Ω at ≦AC300V

R=10Ω at >AC300V

(b) Installation of circuit breaker

Install a circuit breaker on the power side of or inside the power switchboard. The circuit breaker should be of medium-sensitivity and high-speed type (100 mA) to meet inverter, or equivalent type.