How to Clean the Air Filter in Injection Molding Machines

Air filters are installed to prevent the invasion of dust into the control cabinet or control station. Internal filters, if clogged because of fouling, interrupt sufficient air supply or exhaust from the control cabinet or control station. This prevents the plastic molding machine from exhibiting full performance or results in failure of internal electric apparatuses as a result of internal temperature rise. Hence clean filters periodically.

Clean air filters by following the procedure below.

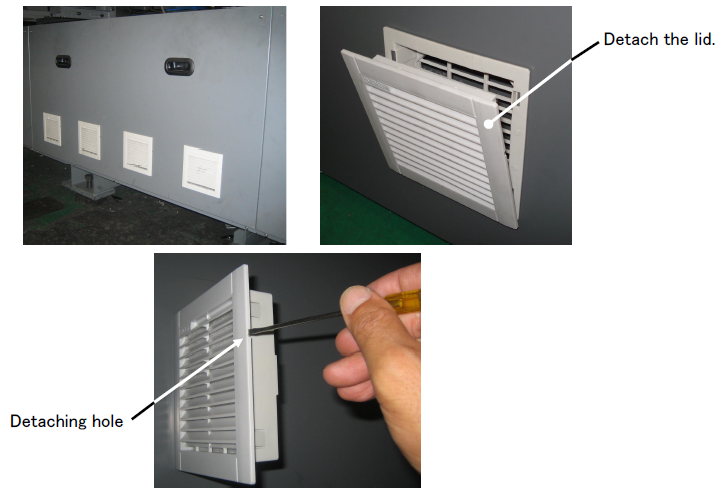

1) Detach the lids of air filters on the control cabinet and control station.

(The photo shows the example of the control cabinet.)

Fit a screwdriver into the detaching hole provided on the side face of the air filter to detach the lid.

2) Take out the filter placed inside.

3) Clean the filter by water washing or vacuuming. Dry sufficiently after water washing. Replace the filter if fouled excessively.

4) Fit the filter on the control cabinet or control station after cleaning.

By TOSHIBA MACHINE CO.,LTD.