How to Check the Barrel and Ring Wearing of Injection Molding Machine

The following phenomenon may possibly be encountered depending on the type of resin used in operation for a long period of time.

(1) The cushion amount fluctuates.

(2) Sink marks cannot be eliminated.

(3) The absolute value of the cushion amount becomes lessened.

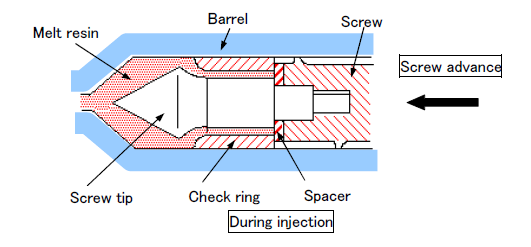

In this case, the barrel or check ring may have been worn. To inspect the wearing state of the barrel or check ring, it is preferable to actually measure the sizes of the barrel or check ring. In the actual case, however, checking by means of double shots is available to simply judge the wearing of the barrel or check ring as described below.

* Double shot is to conduct injection again without mold opening or product take-out after injecting charged melt into the mold cavity.

The screw advances little even if double shots are carried out.

The screw keeps advancing when double shots are carried out.

Extreme care must be exercised for conducting double shots since they may break the mold or the machine depending on operating conditions. When making check by double shots, be sure to observe the following recommended conditions.

[Recommended conditions]

Holding time (TRH1) = 5 s Injection time = 5 s

Holding pressure (PH1) = 100 MPa Injection pressure (PI) = 100 MPa

[14504 psi] [14504 psi]

Holding speed (VH) = 30 mm/s Injection speed (VI1) = 30mm/s

[1.18 in/s] [1.18 in/s]

2) Change molding conditions into [Recommended conditions] for double shots.

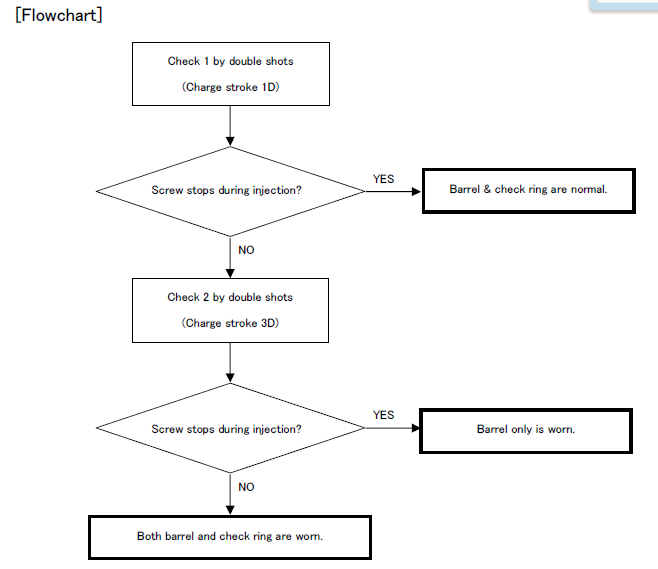

3) Set charge out position (LS5) to 1D (the same as screw diameter).

4) Continuously press the CHG button in MANUAL mode for charge out.

5) Continuously press the INJ button in MANUAL mode.

6) Observe the display of the screw position during injection to check that the screw stops.

7) Repeat the above procedures 4) to 6) three times for the confirmation.

8) The screw is normal when it stops during the injection. If the screw keeps advancing without stop during injection, make the following checks.

9) Set charge out position (LS5) to 3D (three times as long as screw diameter).

10) Continuously press the CHG button in MANUAL mode for charge out.

11) Continuously press the INJ button in MANUAL mode.

12) Observe the display of the screw position during injection to check that the screw stops.

13) Repeat the above procedures 10) to 12) three times for the confirmation.

14) It is judged that only the barrel has become worn when the screw stops during the injection.

If the screw keeps advancing without stop during injection, it is judged that both the barrel and check ring have become worn.

By TOSHIBA MACHINE CO.,LTD.