How to Check Nozzle Alignment on Injection Molding Machines

Check the nozzle center when changing the mold. In the case of a mold without locating ring especially, securely check the nozzle center. Misalignment of the nozzle center may cause resin leakage or mold damage.

Follow the procedure below to adjust nozzle alignment.

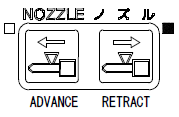

1) After mold mounting, continuously press [ADVANCE] of the NOZZLE button to touch the nozzle tip to the mold for nozzle misalignment check. (At this time insert a piece of paper between the nozzle tip and mold to ease misalignment direction.)

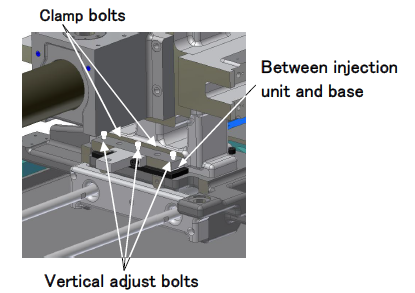

2) Press [RETRACT] of the NOZZLE button to move the nozzle to the retract limit. If the nozzle center shifts vertically, loosen the clamp bolt fixing the injection unit to the base and use adjust bolt to adjust the height of the injection unit and secure vertical alignment.

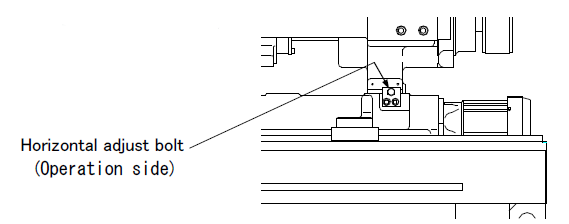

3) If the nozzle center further shifts horizontally, use the horizontal adjust bolt equipped on the operation to adjust the horizontal positioning of the injection unit.

4) After adjusting tighten the clamp bolt.

* Refer to the instruction manual [Appendix] for details of clamp bolt torque of injection unit.

5) Make the nozzle tip touch the mold to check misalignment once again.

To correct vertical nozzle misalignment, control adjusts bolts to uniform following clearances. Non-uniform clearances will cause screw drive mechanism failure. Between injection unit and base: uniform clearances of operation side and non-operation side.

By TOSHIBA MACHINE CO.,LTD.