Forced Grease Mode in Injection Molding Machines

The forced grease mode function is to exhaust air when the air entering in a grease line is observed even after air venting work at grease cartridge replacement (the injection machine does not move smoothly or grease cannot reach each greasing point) or to change grease inside the grease line after a long downtime of the injection machine. Execution of forced greasing effectively prevents damages on ball screws, link pins or linear guides, or motor load increasing.

(1) Operation

The greasing pump operates by forced grease mode and supplies grease to each valve. After the pump pressure reaches to 5MPa (725psi), the greasing pump outputs pump stop signal and stop operation. Then each valve discharges grease to greasing points and the pump starts operation again after one minute.

The pump repeats that procedure five times. (Repeat number setting: C106)

(2) Performance circuit diagram

The performance circuit diagram of forced greasing is as follows.

Operation procedure of forced grease mode:

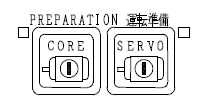

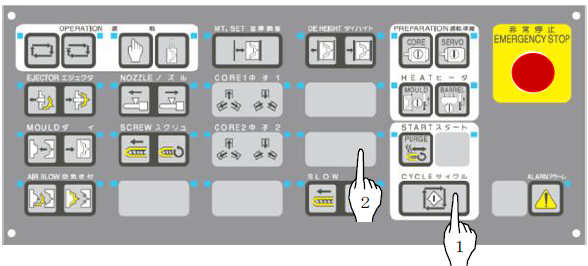

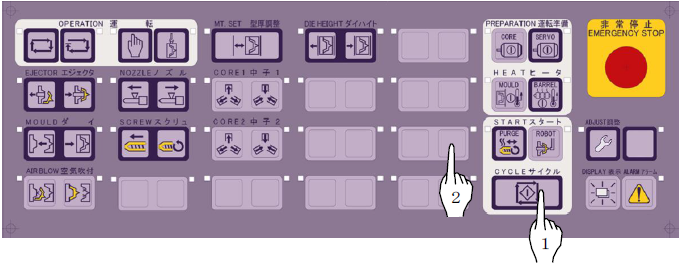

1) Press [SERVO] of the PREPARATION button on the operation controller to turn off the servomotor.

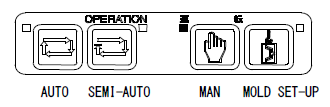

2) Press MOLD SET-UP or MANUAL of the OPERATION button on the operation controller.

3) While pressing the CYCLE button on the operation controller, touch the following button for 3 sec continuously to activate forced grease mode

* In execution of forced grease mode, the LED corresponding to each line flickers.

・Canceling the forced grease mode on the way Follow the procedure the same as the execution of forced grease mode to cancel forced grease mode on the way.

By TOSHIBA MACHINE CO.,LTD.