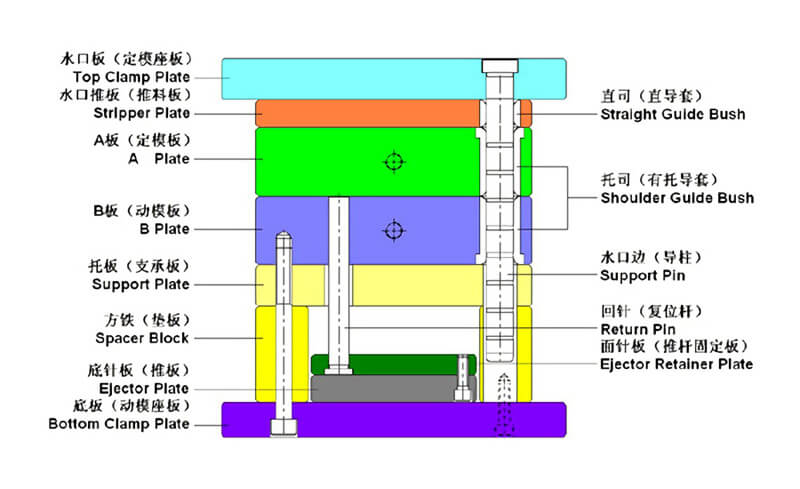

Difference Between Three-plate Mold and Two-plate Mold

The three-plate mold refers to a set of mold blanks consisting of A plate, B plate, and nozzle stripping plate; the two-plate mold batch is composed of A plate and B plate. The difference between the three-plate mold and the two-plate mold is that there is a nozzle stripper. From the perspective of mold structure, the guide posts of the three-plate mold are in the front mold, and the guide posts of the two-plate mold are in the rear mold. From the point of view of use, products with a glue inlet (fine nozzle) feeding method use a three-plate mold; while plastic products with a large nozzle feeding method use a two-plate mold.

Three-plate mold structure description:

The spout edge nail cooperates with the guide sleeve, and then the front mold is guided (the straightening spout plate panel A plate). Secondly, the spout edge nail is not added with a guide sleeve on the entire rear mold, and the template is avoided. Therefore, the spout nail only guides the front mold, while the front and rear molds are guided by the guide post. The guide post guides the rear mold and the front mold (guide B plate and A plate push plate). There is a meson under the spout edge nail to prevent it. If the tie rod is finished, the meson under the spout edge nail can also be limited. The outside is the guide pin guide sleeve inside the spout side nail, of course, there are also the guide post guide sleeve outside the spout side nail.

The differences between the mold nozzle of fine nozzle and large nozzle:

1. The difference between screws; the upper die of the large nozzle mold is fixed with screws and the fine nozzle is not, because the several plates of the front mold have to open the mold panel to separate from the nozzle plate, and the nozzle plate to separate from the A plate

2. The fine nozzle has 4 more side nails than the large nozzle.

3. The fine nozzle has more nozzle push plates than the large nozzle.

4. Large spouts may not have a panel, but fine spouts may not have a panel (otherwise the spout edge nails cannot be fixed).

The mold base models of the three-plate mold (thin nozzle) are:

1.DAI DBI DCI DDI

2.DAH DBH DCH DDH

3.EAI EBI ECI EDI

4.EAH EBH ECH EDH

Remarks:

I stands for 工 -shaped mold;

H stands for straight model mold;

D stands for nozzle plate

E means there is no nozzle plate;

A- The pallet is not pushed;

B- pallet push plate;

C- nothing

D- There is a push plate but no pallet.

Calculation of the length of the three-plate die nozzle:

EAI EBI ECI EDI;

EAH EBH ECH EDH.

The length of the spout nail should be a multiple of 10,

Although the above type does not have a nozzle plate (E represents no nozzle push plate)

But it is also called a three-plate mold, but it is not used for point intersections, but used for special structures such as the front mold row position and the front mold needle extraction.

Simplified fine nozzle

There are 8 types of simplified fine nozzles:

FAI FCI FAH FCH

GAI GCI GAH GCH

F — Simplified fine nozzle mold with nozzle push plate,

G —- Simplified thin nozzle mold without nozzle push plate,

I is still 工 shape,

H is still straight,

A still has a pallet and no push plate,

C still has nothing.

| Three-platen Mold | Two-platen Mold |

|---|---|

| The three-plate mold adds a movable middle plate, also called the gate plate, which is used for the mold of the pin point into the gate material. When the mold is opened, the runner and the product are automatically separated. | The two-plate mold is the simplest of the molds. Part of the cavity is on the moving mold, and the other part is on the fixed mold. When the mold is opened, the product and the runner are left on the side of the moving mold. |

| suitable for point gate mold (two parting surfaces) | suitable for large nozzle mold (one parting surface) |

| The mold gate can use point-in glue, and the gate position can be selected on the surface of the master mold | The mold has only one parting surface, so the structure is simple and the cost of the mold is low |

| A movable middle plate, also called a gate plate, is added, and the runner and the product are automatically separated when the mold is opened. | Part of the cavity is on the moving mold, and the other part is on the fixed mold. When the mold is opened, the product and the runner are left on the side of the moving mold. |

| Three-plate mold is a fine nozzle and the product appearance is relatively better. | The structure of the two-plate mold is simpler and it is a large nozzle; |