Barrel and Nozzle Temperature Setting on Injection Molding Machines

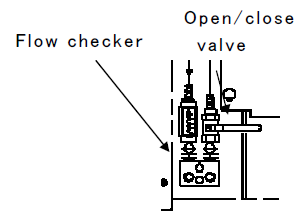

[1] Cooling water running under hopper

Check water flow with the flow checker on the non-operation side of the machine. If cooling water is not running, open the stop valve to run cooling water under the hopper.

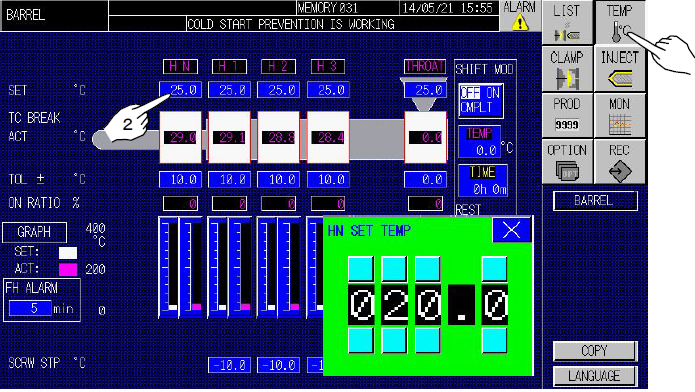

[2] Setting of barrel temperature (temperature, tolerance)

Set barrel temperature matched to molding material to be used on the [TEMP] screen of INJECTVISOR.

1) Touch the [TEMP] screen selector button.

2) Touch [HN], [H1] – [H3] and [THROAT(option)] on the [TEMP] screen to successively open the setting window to set molding temperature of each control zone. (Number of barrel zones differs by machine model.)

If the actual temperature is lower than the preset hopper throat temperature, the solenoid valve (M161), which is installed in the cooling water circuit under the hopper, is turned OFF to stop cooling water running under the hopper.

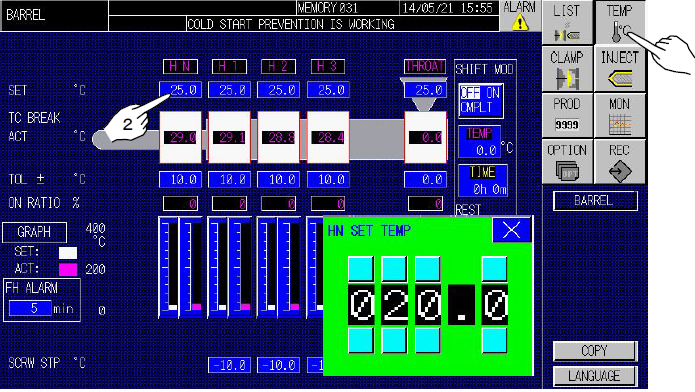

[3] Setting of barrel temperature tolerance (Alarm)

Display the [BARREL] or [MON MGT2] screen to set temperature tolerance.

1) Touch the [TEMP] screen selector button.

2) Touch the [TOL] to successively open the setting window to set temperature tolerance of each control zone.

3) Touch [ALARM SELECT] buttons on [MON MGT2] screen to change alarm [ON/OFF].

[4] Press [BARREL] of the HEATER button on the operational controller to turn on the barrel heater.