Auxiliary Equipment Precaution of Toshiba Injection Molding Machines

(1) We are liable for the interaction between the machine and auxiliary equipment, only when we design the interface for the auxiliary equipment (product take-out robot, mold changer, mold clamp device, mold temperature controller, or conveyor, etc.).

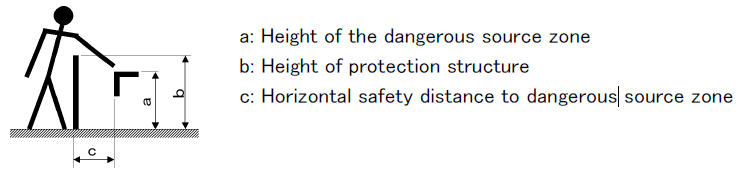

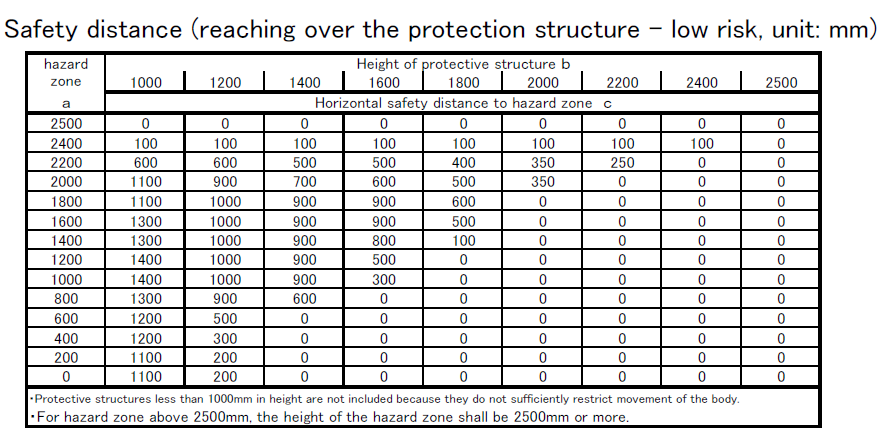

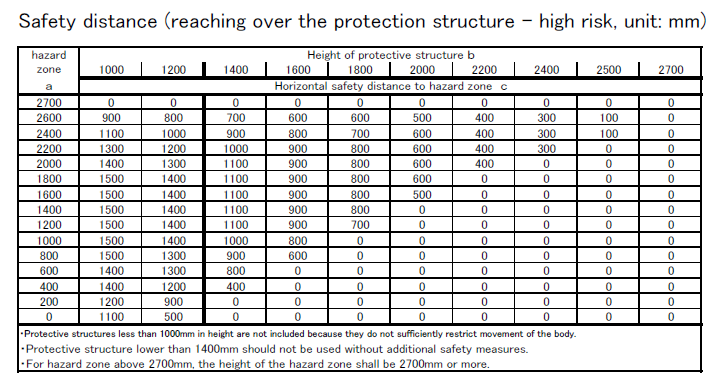

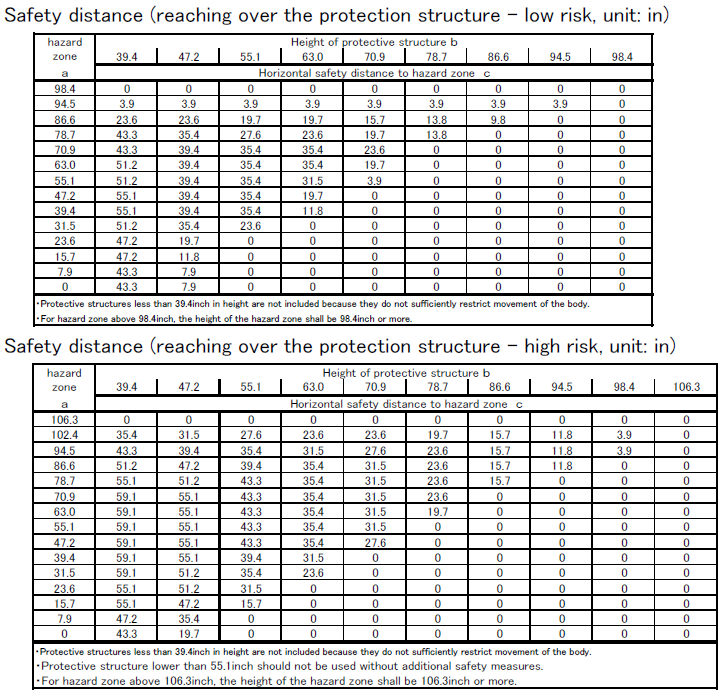

(2) When removing a mechanical cover, door or safety device to mount auxiliary equipment, be sure to install the cover or protection device for securing the safe distance to prevent reaching of human body to a dangerous place. Refer to the following table for safety distance.

(3) When the auxiliary equipment is dismounted, be sure to restore the original cover, door or safe device originally attached to the machine.

(4) The height and safety distance of the protective device with regard to designing of this machine have been calculated using the specified working position (the ground plane of the machine or the working space included in the machine) as a reference surface. If a user requires an additional supplementary working space for the operation of the machine or wishes to increase the machine installation space, the height and safety distance of the related protective device must be calculated again (see the GB 23821 Standards). If further required, the related protective device itself must be additionally provided. Please note that we are not responsible for any trouble that may be caused by modification of the working position of the machine without approval of our company.