Alarm Code List and Error Resetting Procedures of Toshiba Injection Molding Machines

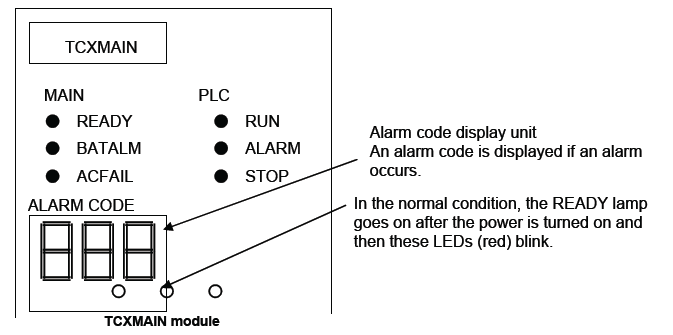

Take the proper countermeasures shown in the list below if an alarm code is displayed in the TCXMAIN module of the INJECTVISOR-S51(S50)/V50. Please notify Toshiba Machine of the alarm code and occurrence condition, if the error is not reset even after taking the countermeasures shown below.

| Alarm code | Error description | Reset procedure |

|---|---|---|

| Item 1 | Description | Description |

| 001 | Program area check sum error | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module, etc. Or, the ROM may be disconnected from the IC socket in the TCXMAIN module. Check connection if possible. |

| 002 | Work RAM rd/wr check error | An error occurs in read/write check in the area from 0C20000H to 0CFF7FFFH of the SD-RAM. |

| 003 | No V6PC module | Turn off the main power, and check the mounting condition of the TCXMAIN module. And turn it on again. |

| 004 | V6PC common RAM error | Turn off the main power, and check the mounting condition of the TCXMAIN module. And turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module, etc. |

| 008 | Parameter check sum error | Turn off the main power once, and turn it on again. Check the molding conditions. If they are proper, restart operation. |

| 012 | No V3I0 board in TCPIO module | Turn off the main power, and check the mounting condition of the TCPIO module (V3IO). Turn on power again. If the error recurs, it may be caused by the defective TCPIO module (V3IO), etc. |

| 018 | No V3I0 board in TCPIO module (R1) | Turn off the main power, and check the mounting condition of the TCPIO module (V3IO). Turn on power again. If the error recurs, it may be caused by the defective TCPIO module (V3IO), etc. |

| 019 | No TCDACA module | Turn off the main power, and check the mounting condition of the TCDACA module. Turn on power again. |

| 021 | No TCDACA module (TX1 D/A error) | Turn off the main power, and check the mounting condition of the TCDACA (TX1) module. Turn on power again. |

| 022 | No TCDACA module (TX2 D/A error) | Turn off the main power, and check the mounting condition of the TCDACA (TX2) module. Turn on power again. |

| 023 | No TCDACA module (RX1 D/A error) | Turn off the main power, and check the mounting condition of the TCDACA (RX1) module. Turn on power again. |

| 024 | No TCDACA module (RX2 D/A error) |

Turn off the main power, and check the mounting condition of the TCDACA (RX2) module. Turn on power again. |

| 026 | Molding condition check sum error | Turn off the main power once, and turn it on again. Check the molding conditions. If they are proper, restart operation |

| 027 | Backup data check sum error | Turn off the main power once, and turn it on again. Check the molding conditions. If they are proper, set the scale and restart operation. |

| 029 | Injection scale counter error (Hyd.) | Turn off the main power, and check the mounting condition of the TCPIO module (V3IO). Turn on power again. If the error recurs, it may be caused by the defective TCPIO module (V3IO), etc. |

| 030 | Clamping scale counter error (Hyd.) | Turn off the main power, and check the mounting condition of the TCPIO module (V3IO). Turn on power again. If the error recurs, it may be caused by the defective TCPIO module (V3IO), etc. |

| 032 | A/D conversion error | Turn off the main power, and check the mounting condition of the TCPIO module (V3IO). Turn on power again. If the error recurs, it may be caused by the defective TCPIO module (V3IO), etc. |

| 033 | No R12-D/A board (Hyd.) | Turn off the main power, and check the mounting condition of the TCPIO module (V3IO). Turn on power again. If the error recurs, it may be caused by the defective TCPIO module (V3IO), etc. |

| 035 | Feeder output error | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCDACA (FE) module, etc. |

| 036 | Feeder rotation input error | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCDACA (FE) module, etc. |

| 037 | Clamp position back-up error (Hyd.) |

After adjust clamp position, Turn off the main power once, and turn it on again. |

| 038 | Screw position back-up error (Hyd.) |

After adjust screw zero position, Turn off the main power once, and turn it on again |

| 043 | No TCPSD module | Turn off the main power, and check the mounting condition of the TCPSD module. Turn on power again. |

| 044 | TCPSD common RAM error rd/wr check error |

Turn off the main power, and check the mounting condition of the TCPSD module. Turn on power again. If the error recurs, it may be caused by the defective TCPSD module, etc. |

| 045 | No TCADCA module (Internal mold pressure) |

Turn off the main power, and check the mounting condition of the TCADCA module. Turn on power again. |

| 049 | Monitor output 1 D/A error | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCDACA module, etc. |

| 050 | Monitor output 2 D/A error | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCDACA module, etc. |

| 051 | Monitor output 3 D/A error | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCDACA module, etc. |

| 053 | No TCXSV (1) module | Turn off the main power, and check the mounting condition of the TCXSV (1) module. Turn on power again. |

| 055 | No V5SR board in TCXIS(1) module (Load cell for EJE.) |

Turn off the main power, and check the mounting condition of the TCXSV module (V6SR). Turn on power again. |

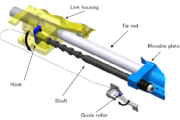

| 056 | No TCADCA module (Link housing position) | Turn off the main power, and check the mounting condition of the TCADCA module. Turn on power again. |

| 059 | Monitor output 4 D/A error | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCDACA module, etc. |

| 060 | Monitor output 5 D/A error | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCDACA module, etc. |

| 061 | Monitor output 6 D/A error | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCDACA module, etc. |

| 062 | Mold clamping A/D error | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCDACA module, etc. |

| 063 | No V3II module | Turn off the main power, and check the mounting condition of the TCPIO module (V3IO). Turn on power again. If the error recurs, it may be caused by the defective TCPIO module (V3IO), etc. |

| 066 | No inverter board | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCDACA module, etc. |

| 067 | No TCXSV (2) module | Turn off the main power, and check the mounting condition of the TCXSV (2) module. Turn on power again. |

| 069 | No TCXSV (3) module | Turn off the main power, and check the mounting condition of the TCXSV (3) module. Turn on power again. |

| 071 | No TCXSV (4) module | Turn off the main power, and check the mounting condition of the TCXSV (4) module. Turn on power again. |

| 090 | ABNORMALITIES IN MUTUAL SURVEILLANCE | Turn off the main power, and check the mounting condition of the TCXIS module. Turn on power again. |

| 093 | WATCHDOG ERROR (TCXIS) | Turn off the main power, and check the mounting condition of the TCXIS module. Turn on power again. |

| 094 | Category 0 input turns on during the servo turned on | Check the wire and circuit of category 0 input which is A2 and B2 pin of CNSAFE1 connector for the TCXIS module |

| 095 | Category 1 input turns on during the servo turned on | Check the wire and circuit of category 1 input which is A3 and B3 pin of CNSAFE1 connector for the TCXIS module. |

| 096 | Category 0 input turns on with the servo turned on | Check the wire and circuit of category 0 input which is A2 and B2 pin of CNSAFE1 connector for the TCXIS module |

| 097 | Category 1 input turns on with the servo turned on | Check the wire and circuit of category 1 input which is A3 and B3 pin of CNSAFE1 connector for the TCXIS module. |

| 098 | External contactor turned off forcibly. |

Check connection of pin number 3 and 4 on the CNMST connector of servo power supply. |

| 099 | Servo power not connected | Check connection of the cable (brown connector) between the servo power supply and the servo amplifier. |

| 09A | Servo module 24V or jumper not connected | Check connection of the 24V power supply (bottom face) or the jumper connector (LAN connector) of the servo module. |

| 100 | Initial clear not done | Initial clear is not done. This code does not appear in normal condition. |

| 101 | Power Off detection | Turn off the main power once, and turn it on again. |

| 102 | System failure | Turn off the main power once, and turn it on again. |

| 103 | V6PC watchdog error | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| 104 | HMI communication error | Turn off the main power once, check connection of the Ethernet cable between TCXMAIN and HMI, and turn on power again. |

| 108 | Watchdog error | Turn off the main power once, and turn it on again |

| 109 | Clamping scale disconnection (Hyd.) | Turn off the main power once, check connection of the clamping scale and cable, and turn on power again. |

| 110 | Clamping scale (ZINIC) latch error (Hyd.) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCPIO module (V3IO), etc. |

| 111 | Injection scale disconnection (Hyd.) | Turn off the main power once, check connection of the injection scale and cable, and turn on power again. |

| 112 | Injection scale (ZINIC) latch error (Hyd.) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCPIO module (V3IO), etc. |

| 113 | V3IO A/D conversion error | Turn off the main power, and check the mounting condition of the TCPIO module (V3IO). Turn on power again. If the error recurs, it may be caused by the defective TCPIO module (V3IO), etc. |

| 115 | Ejection Power Alarm (Hyd.) | Turn off the main power, and check the mounting condition of the TCPIO module (V3IO). Turn on power again. If the error recurs, it may be caused by the defective TCPIO module (V3IO), etc. |

| 118 | +15 V error | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective V21CB module, etc. |

| 119 | -15 V error | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective V21CB module, etc. |

| 124 | Internal mold pressure A/D conversion error | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCADCA module, etc. |

| 125 | V3II board A/D conversion error | Turn off the main power, and check the mounting condition of the TCPIO module (V3II). Turn on power again. If the error recurs, it may be caused by the defective TCPIO module (V3II), etc. |

| 126 | Insufficient Battery | Change the battery on TCXMAIN. |

| 128 | TCXMAIN switch reading error | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module, etc. |

| 129 | Clamp internal conversion error | Set PCH to a value other than “0”. If the error recurs, turn off power once and turn it on again. |

| 130 | Toggle table error | Turn off power once, and turn it on again. If the error recurs, it is necessary to confirm internal data |

| 131 | Communication time-out between panels | Turn off the main power, check connection of the cable between the HMI and operation panel, and turn on power again |

| 234 | Edit file check sum error | Check the molding conditions in the edit file. If they are proper, overwrite data in the edit file. Then, turn off the main power once, and turn it on again. |

| E00~E99 | System error | Turn off the main power once, and turn it on again. |

| 311 | Servo error 1 axis (over-speed) | Press the Alarm Reset button. |

| 312 | Servo error 1 axis (speed error) | Press the Alarm Reset button. |

| 313 | Servo error 1 axis (excessive positional error) | Press the Alarm Reset button. |

| 314 | Servo error 1 axis (over-torque) | Press the Alarm Reset button. |

| 315 | Servo error 1 axis (encoder error) | A diagnostic message is displayed on the HMI screen. See the Reset procedure. |

| 316 | Servo error 1 axis (servo error) | A diagnostic message is displayed on the HMI screen. See the Reset procedure. |

| 317 | Servo error 1 axis (over-stroke) | Press the Alarm Reset button. Return the shaft to the normal position in the Emergency mode. |

| 318 | Servo error 1 axis (Sync. shaft excessive positional error) | Press the Alarm Reset button. |

| 319 | Servo error 1 axis (electronic thermal error) | Press the Alarm Reset button. |

| 31A | Servo error 1 axis (encoder backup error) | Press the Alarm Reset button. |

| 31B | Servo error 1 axis (Sync. shaft excessive torque error) | Press the Alarm Reset button. |

| 32* | Servo error 2 axis | (* represents 1,2,3,4,5,6,7,8,9,A,B. The error reset procedure is same as Servo error 1 axis.) |

| 33* | Servo error 3 axis | (* represents 1,2,3,4,5,6,7,8,9,A,B. The error reset procedure is same as Servo error 1 axis.) |

| 34* | Servo error 4 axis | (* represents 1,2,3,4,5,6,7,8,9,A,B. The error reset procedure is same as Servo error 1 axis.) |

| 35* | Servo error 5 axis | (* represents 1,2,3,4,5,6,7,8,9,A,B. The error reset procedure is same as Servo error 1 axis.) |

| 6** | Internal file check sum error | Check the molding conditions in the internal memory **. If they are proper, overwrite data in the internal memory **. Then, turn off power once, and turn it on again. (** represents a memory number from 001 to 099.) |

| 7** | Internal file check sum error | Check the molding conditions in the internal memory **. If they are proper, overwrite data in the internal memory **. Then, turn off power once, and turn it on again. (** represents a memory number from 100 to 199.) |

| 8** | Internal file check sum error | Check the molding conditions in the internal memory **. If they are proper, overwrite data in the internal memory **. Then, turn off power once, and turn it on again. (** represents a memory number from 200 to 299.) |

| 900 | Internal file check sum error | Check the molding conditions in the internal memory **. If they are proper, overwrite data in the internal memory **. Then, turn off power once, and turn it on again. (** represents a memory number 300.) |

| C00 | System error (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C02 | ROM error (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C01 | RAM error (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C30 | Backup data error (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| U** | I/O card error (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| H** | Remote I/O error (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C62 | Too many functions used (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C31 | Watchdog error (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C64 | Label undefined (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C63 | Operation code error (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| P00 | Extended power supply error (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C61 | Interrupt program error (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C65 | Label duplicate undefined (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C32 | Temperature error (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C40 | Battery error (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| L** | PLC link error (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C60 | Cycle time-over (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| P60 | Instantaneous power failure (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C70 | Function undefined (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| F** | Fuse blow-out (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C71 | I/O mismatching (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| L60 | Too many link masters used (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| CCC | Replacing I/O card (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C41 | EEPROM error (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| C72 | Link table error (PLC) | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |

| E0* | Intelligent module abnormal | Turn off the main power once, and turn it on again. If the error recurs, it may be caused by the defective TCXMAIN module (V6PC), etc. |