Precautions for the Electric System of Toshiba Injection Molding Machines

(1) Electric construction for auxiliary equipment

Do not feed power source to any auxiliary equipment from the secondary circuit of main breaker in the electric cabinet of the injection molding machine. Feeding source from electric circuit of the machine will be the cause of a fire and machine malfunctions.

(2) Grounding the machine and control cabinet

Ensure that the machine frame and control cabinet is grounded and that connections are not corroded. Regularly exercise extreme care to avoid short-circuiting.

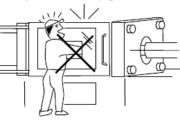

(3) Maintenance, inspection, and connector removing

Be sure to turn off the power before maintenance or inspection of electric circuit or removing the connectors. Failure to comply can cause a serious accident resulting in injury or death.

(4) Inspection for heater wiring

Ensure that the heater wiring is not loose and that bare wires are not exposed. Be sure to turn off the power and measure voltage at inspection points to ensure that the power is off before inspection. Insulate the heater wire connections with heat-resistant tape. Polyvinyl tape should not be used since it melts.

(5) Opening/closing the control cabinet gate

Be sure to close the control cabinet gate (or cover) before operating the machine. If left opened, dust or refuse enters the cabinet possibly causing trouble or electric shock.

(Turn off the power and clean the cabinet inside once in half-year.)

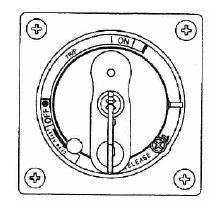

(6) Power ON/OFF

Securely use the main breaker to turn the power on and off. Be sure to use your right hand to turn on and off. Keep your left hand away from the instruments and the machine body.

(7) Stopping the machine

To stop the machine, press [MAN] or [SET-UP] of the OPERATION selector button.

(8) Precautions for electric parts and equipment check

a.) Ensure that the main power is off.

b.) Take all tools and other materials away from the check area before checking with extreme care, if required with current kept supplied to the machine. Ensure that the work area is dry. Use electrically insulated shoes and gloves.

c.) Avoid wearing any metallic material such as a tool, ring, watch necklace, or eyeglasses with a metal frame.

(9) Do not leave the machine with covers or control cabinet gates left opened.

(10) Check the power cable for the servo motor drive unit for damage periodically.

Production under molding conditions with high motor load factors may melt the coating of power cable resulting in an accident. Adjust condition so that the motor load factor on the operation monitor does not exceed 100 %.

For details of the motor load factor, refer to Section 4.8 Operation Monitor of Operation Guide Book of INJECTVISOR-V50, Section 5.7.3 Motor Load Factor Display of Operation Guide Book of INJECTVISOR-S51.