Plastic PP Injection Molding Process Settings

Polypropylene (PP)

Heating Temperature:

Barrel temperature feeding zone 30~50°C (50°C)

Zone 1 160 ~ 250 ° C (200 ° C)

Zone 2 200~300°C (220°C)

Zone 3 220 ~ 300 ° C (240 ° C)

Zone 4 220 ~ 300 ° C (240 ° C)

District 5 220 ~ 300 ° C (240 ° C)

Nozzle 220 ~ 300 ° C (240 ° C)

The temperature in parentheses is recommended as the basic set value, the stroke utilization is 35% and 65%, and the ratio of module flow length to wall thickness is 50:1 to 100:1.

Melt temperature: 220 ~ 280 ° C

Barrel constant temperature: 220 ° C

Mold temperature: 20 ~ 70 ° C

Injection pressure: has good flow performance, avoiding excessive injection pressure of 80 ~ 140MPa (800 ~ 1400bar);

Except for some thin-walled packaging containers, it can reach 180MPa (1800bar)

Holding pressure: avoiding the shrinkage of the product, it takes a long time to hold the product (about 30% of the cycle time); about 30% to 60% of the injection pressure

Back pressure: 5~20MPa (50~200bar)

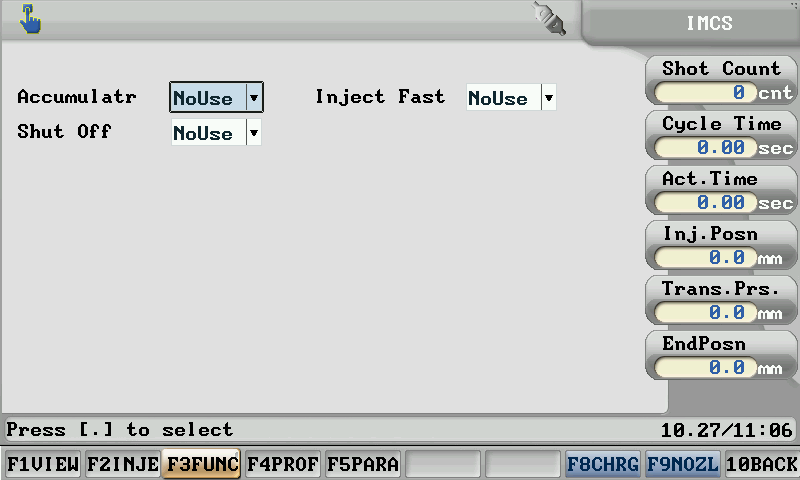

Injection speed: high injection speed (with accumulator) for thin-walled packaging containers; medium injection speed is often suitable for other types of plastic products

Screw speed: high screw speed (line speed of 1.3m / s) is allowed, as long as the plasticization process is completed before the end of the cooling time

Metering stroke: 0.5 ~ 4D (minimum ~ maximum); 4D metering stroke is very important to provide a long enough residence time for the melt

Residual material amount: 2~8mm, depending on metering stroke and screw speed

Pre-drying: no need; if the storage conditions are not good, dry at 80 ° C for 1 h

Recovery rate: 100% recycling

Shrinkage: 1.2 to 2.5%; high degree of shrinkage; no shrinkage after 24h (shrinkage after molding)

Gate system: point gate or multi-point gate; heated hot runner, insulated hot runner, in-situ sleeve; gate location is at the thickest point of the product, otherwise it is prone to large shrinkage

Machine downtime: no special cleaning work with other materials; PP temperature rise

Barrel equipment: standard screw, standard three-stage screw; for packaging container products, mixing section and shear section geometry special (L: D = 25: 1), straight-through nozzle, check valve