Injection Stretch Blow Moulding Process

Injection stretch blow moulding process is best known for manufacturing high quality and high clarity products. Exactly it`s PET water bottles. And of caused some other products are using the same molding process, like baby feeding bottles, outdoor drinking water bottles,cosmetic bottles,etc.

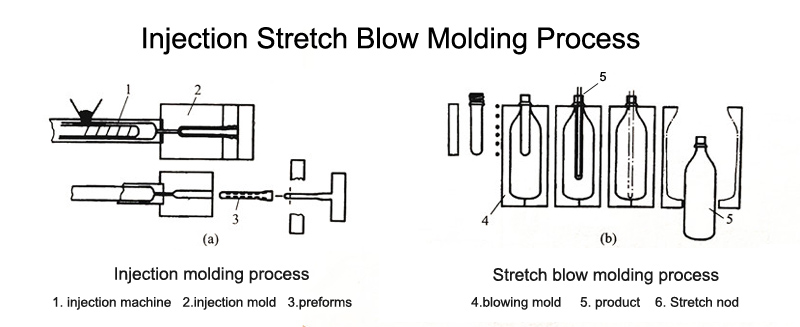

The injection stretch blow molding process includes below 2 process:

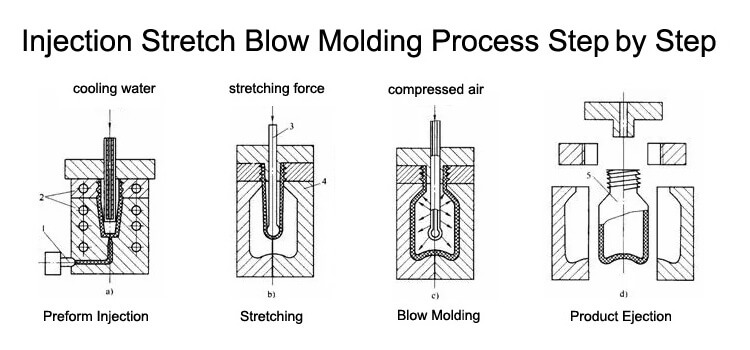

1. Injection molding process: The raw material is heat and melt with a screw and barrel,and then injection to a preform injection mold.

2. Stretch and blow molding process: The preform is transferred to a blow mold before it`s cooled or reheated to the glass transition temperature for stretching, Then it was stretched in axial direction with a stretch rod, then release compressed air into the preform to force against the inside of the blowing mold, when it was cooled we have the mold shape products.

Some people may be confused with the injection blow molding process and injection stretch blow molding process. Just noted there is only one different thing: stretching process.

Injection stretch blow molding means the preforms must be stretched longer before blowing. It`s is used on longer/high containers or with very good quality products like expensive cosmetic bottles.

Below animator may help you better understand what the STRETCH meaning:

| Full Name | Short Name |

|---|---|

| Polyethylene – Terephthalate | PET |

| Polyvinyl chloride | PVC |

| Polypropylene | PP |

| Polystyrene | PS |

| Tritan | Tritan |