It is very important for PET preform Mould Lubrication System which have sufficient stiffness and strength. There are many factors should take care for a mold maker when starting a PET perform mould designs.

The lubrication system of the mold plays a vital role in the PET preforms mould quality. It is the key in the PET preforms forming process. The material used for PET performs mould should be strictly select with considering their characteristic. Each part should be helpful for the mold gliding property, stability, accuracy, stiffness and strength, etc.

There are two major categories for a mold making materials: metal and metal materials. The metal materials is mostly includes different no. of steel, aluminum alloy, etc. And the non-metallic materials are mainly have gypsum, cement, FRP, wood and so on.

No matter what materials is used, but the preform mold must meet below requirements:

1. Reach the PET performs` accuracy of size. This is the basic rule you should keep in mind during the whole process of a PET preform mould design.

2. Make sure the mold have enough sufficient rigidity and strength to keep the quality stability and life time. Ensure it can protect the mold from deformed and damaged.

3. The treatment process should meet the plastic products characteristic. The mold should not be affect by the resin and auxiliary material erosion. Oppositely, it can affect on the resin to cause problems.

4. The material should be help on PET preform demoulding and muse be good for long life time.

5. The material in used should be economic and easy to get. We should take the balance for the quality and cost of the mold. PET Preform Mould should be based on the glass fiber reinforced plastic hydrochloric acid tank molding technology and product precision and surface quality, reasonable selection of mold materials.

6. For the lubrication materials, we can two ways for how to select the right stuff:

A) Choose Lubricate material by how it works

There are two methods for the lubrication system: Manual brushing and automatic spraying. It`s most used with manual brushing in nowadays. But its more and more molds with auto-spraying systems.

B) Choose Lubricate material by where it is used

The use of the site is divided into: initial mold pre-coating spray coating; hand-brushing universal mold lubrication paint, specially used in the pressure-blowing method wide-mouth bottle lubrication paint, specialized for small glass bottles and die-specific lubrication coating, special for the specific type, Jar Preform Mould special large-scale glass bottle of the initial mold lubrication coating; The bottle shoulder crack special rubber agent and so on many different grades product kind.

PET preform Mould Lubrication System Design is very important which should think about it since the mold design starts. It go through the whole PET preform mold manufacturing process. It affects the PET preform molds life and how easy for the maintenance.

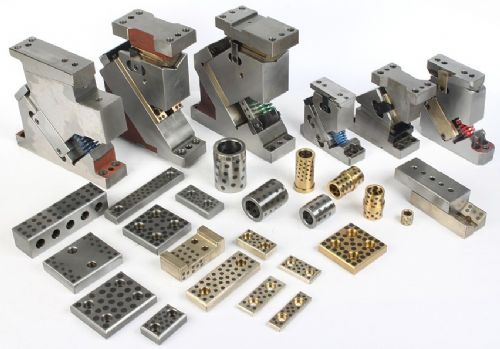

The common Lubricate Material for PET preform Mould for choice:

1. Substrate material: high strength brass CAC304 inlaid graphite, # 500SP.

2. Substrate material: cast iron GC250 inlaid graphite, # 500F.

3. Substrate material: carbon steel SM45C inlaid graphite, # 500CS.