Heater Maintenance and Inspection of Injection Molding Machines

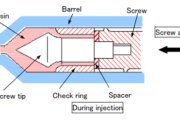

Band heaters or aluminum-cast heaters are usually used for the barrel. Most of our injection molding machines use the former, band heaters in which Nichrome wire is placed between stainless sheets and insulated with mica. Follow the procedure below for the maintenance and inspection of the heaters.

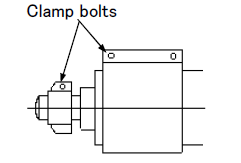

1) Heater band failure is mainly caused by improper tightening. The watt density of heater is about 3 ~ 5 W/cm2. A less contacting area with the barrel results in self-heating and eventually in disconnection. Thus retighten heaters while hot at least once a month.

2) When retightening the above, also inspect screws of heater wiring (such as screws for

the terminal box, contactors, etc.) for looseness.

3) Heaters should show a few megaohms or more of insulation resistance after being heated once. Insulation resistance of less than one megaohm (1MΩ) will adversely affect the human body due to leak current. Investigate the cause of the problem and replace heaters if no cause is found.

4) When retightening the above, also inspect thermocouples for secure insertion.

Securely turn off the power and measure voltage at the power source to check power off before heater inspection.

By TOSHIBA MACHINE CO.,LTD.