How to Inspect Lubrication System of Injection Molding Machines

Inspect the lubrication status of the respective unit for the following points.

(1) Check if lubrication is insufficient.

(2) Check if grease is discolored, fouled or solidified.

(3) Check if refuse or foreign matter is caught.

(4) Check the sliding surface for scratches.

When grease on the ball screw is fouled or catching foreign matter, wipe off the grease with a piece of clean cloth. Never use a solvent for this purpose. Using a solvent cuts oil film while possibly shortening ball screw life.

When the mold has not been changed for a long time, press OPEN and CLOSE of the DIE HEIGHT button to open and close the platen one time for the purpose of lubricating the mold thickness setter. At this time move the platen for the full stroke of DIE HEIGHT.

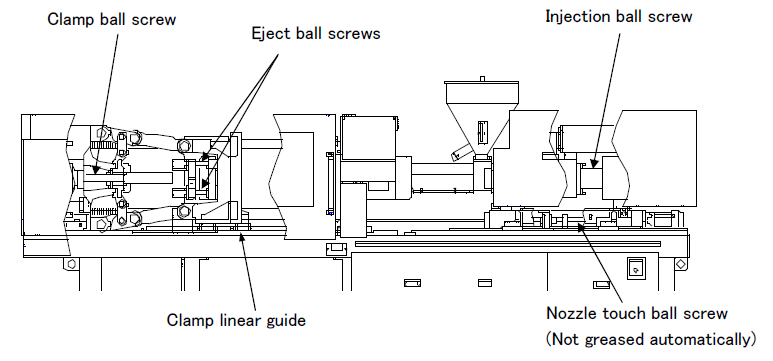

The following portions are equipped with automatic greasing circuits. Be sure to use high load-resistant high-performance grease recommended by us for the automatic greasing circuit.

1) Injection ball screw 2) Injection linear guide

3) Ball screw for mold open/close

4) Crosshead guide bush

5) Link pin,

6) Link housing lower slideway 7) Mold thickness setting mechanism nuts

8) Ejection ball screw

Refer to the attached Lubrication Specification for recommended grease by us or greasing points.

Clamp ball screw

Eject ball screws

Injection ball screw

Using the machine after the grease cartridge becomes empty with no lubrication may possibly cause ball screw, ball bearing or linear guide to be damaged irreparably. Securely replace the grease cartridge when the alarming comment is on.

By TOSHIBA MACHINE CO.,LTD.