Weekly Inspection on Injection Molding Machines

The operator should check the following items weekly in machine operation.

| Item | Inspection Procedure | Check/Measure | |

|---|---|---|---|

| Ejector Pin | Inspect ejector pins with the mold dismounted by following the procedure below. Check that ejector pins do not protrude from the mold mounting face of the movable platen when the ejector plate reaches the retract limit. When not dismounting the mold, check if no clearance exists between ejector pins and threaded portions of the ejector plate. | Tighten the ejecting rod of loose. | |

| Band Heater | Visually check the following: 1) Set bolts for loosening 2) Adhering resin 3) Lead wire for failure 4) Lead wire terminal for loosening |

1) Tighten set bolts. 2) Remove adhered resin. 3) Replace the lead wire. 4) Tighten terminal. |

|

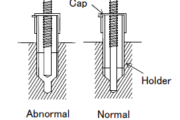

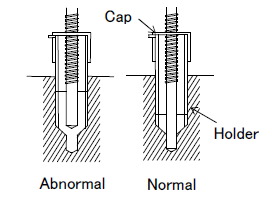

| Thermocouple insertion | Check if thermocouple tip is in close contact with barrel hole bottom.  |

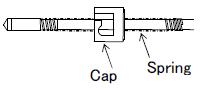

If abnormal, adjust cap position to make the tip of thermocouple contact the barrel hole bottom. Adjust thermocouple cap position by rotating the cap on spring  |

|

| *DANGER: Securely turn off the power and measure voltage at inspection points to check power OFF before heater and thermocouple inspection. | |||