Daily Inspection of Injection Molding Machines

The operator should check the following items every day in machine operation.

| Item | Inspection Procedure | Check/Measure | |

|---|---|---|---|

| Moving section such as clamp or injection units | Visually and aurally inspect the machine for abnormal movement, noise or vibration. | Investigate and eliminate the cause. |

|

| Cooling water pipe and fitting | Check pipe fittings for water leakage and pipes for breakage and water leakage. | Tighten fittings if water leakage is found. Wrap thread fitting with seal tape if water leakage does not stop. | |

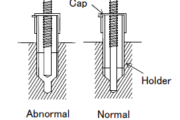

| Flow checker (return port of cooling water) | Check if sufficient water runs through the flow checker. Also make check for clogging due to water deposit. |

If insufficient, inspect piping for water leakage. | |

| Moving section | Visually check for loosening. | If loose, tighten bolts and nuts with a wrench. | |

| * By TOSHIBA MACHINE CO.,LTD | |||