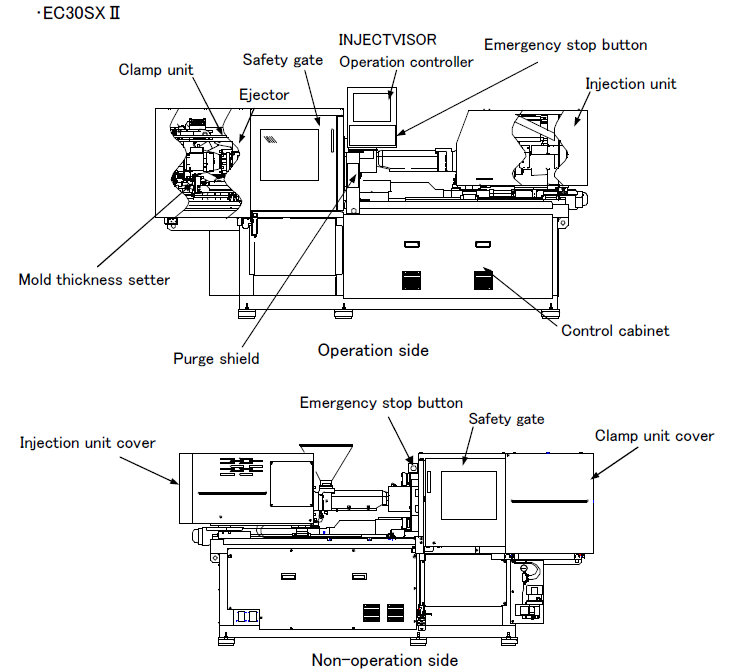

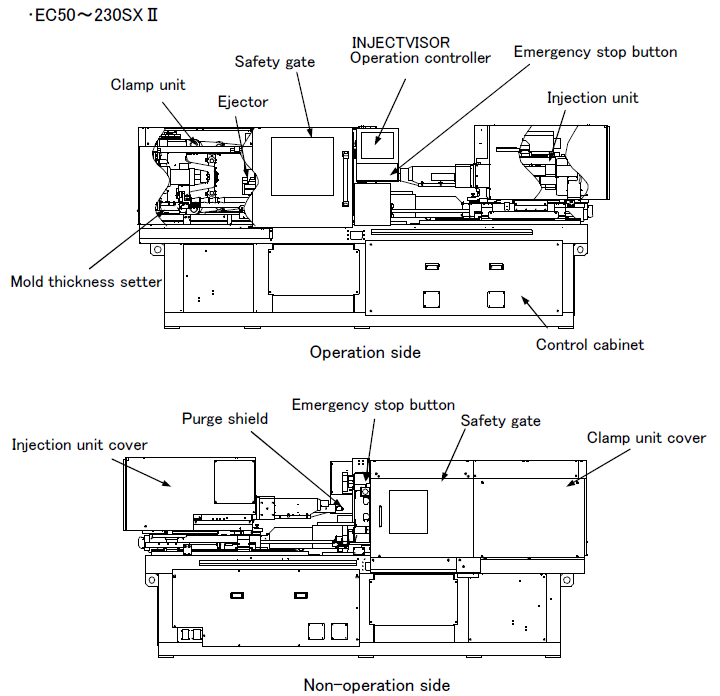

Main Unit and Equipment of Toshiba Injection Molding Machines

1. Outline of Injection Molding Machine

The injection molding machine, provided with full electric control system with the use of AC servomotors as the drive source for injection and clamping, operates MANUALLY, SEMI-AUTOMATICALLY or AUTOMATICALLY.

The machine can be applied to various types of thermoplastic resin to produce high-quality molded products. The machine operates at high-speed cycle rate while assuring high accuracy on products, energy saving, low operation side, and clean environment.

The machine also assures the safety strongly, such as preventing mold closing mechanically as well as interrupting the electric circuit of clamp unit upon opening of the safety gate.

1.1 Main Unit and Equipment

The machine is full-type electrically driven injection molding machine equipped with four units of AC servomotors for injection, charging (screw running), ejection and mold opening/closing. The machine is also equipped with geared motors for die height adjustment and nozzle touching.